What is AniCAM HD™ 3D Scanning Microscope?

The AniCAM HD™ 3D Scanning Microscope is the capturing device for Troikas Quality Control Applications to measure Flexo-Plates, Anilox Rolls, and Gravure Cylinders. These applications are proven to enable printers to know the condition of their rolls or plates and make savings by reducing press setup time and waste.

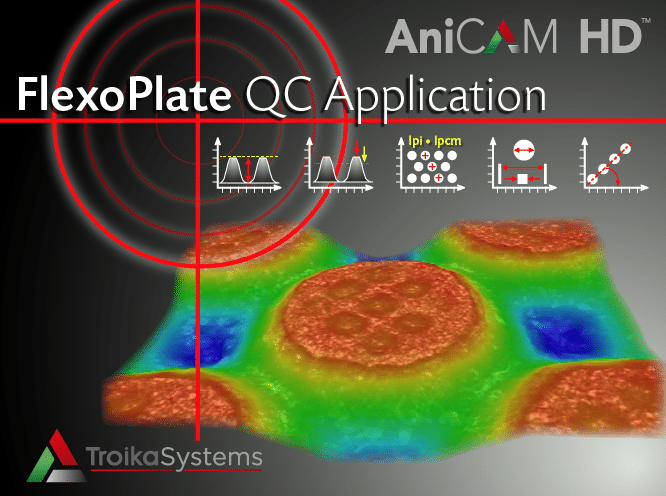

Its design allows the camera to be placed on flat material and/or ceramic, chrome, or steel cylinders. The internal high-tech motors can be stepped in fractions of a micron. The 3D images are generated from a number of “photos” taken at different focus depths. The software combines the sharp parts of each image and creates the 3D representation of the substrate for which depth, opening, volume, dot shape, and profile can be analyzed.

What can be measured?

- Average cell volume

- Cell frequency in lpi or lpcm

- Cell opening diameter

- Cell wall width

- Cell depth

- Cell angles

Coaxial and Radial Light

The camera unit is equipped with two light sources: Coaxial light is directed straight down onto the surface of the material and reflected back up the same path and onto the camera. It is essential for the Autofocus and readings. The Radial Light is a 2 x 9-LED ring system that is designed to radiate light into the cells, which leads to an optimum illumination for most accurate readings.

Key Benefits of AniCAM HD™

A very practical and easy to use tool that will ensure your anilox rolls are properly identified with volume measurement, screen count, screen angle, cell opening and wall measurements, all done in just a few minutes. Knowing the condition of the Anilox in the heart of your press, through proper identification and verification, gives increased assurance of the final printed result.

Verifying the volume of a set of anilox rolls is essential for maintaining ink balance on press. Having a set of rolls that you know have similar volumes will reduce time consuming and costly ink strengthening and its associated work-off ink; it can reduce the need for ink extending and some work-off ink inventory. All measurement information and images can be printed or exported for use in 3rd party software (like Excel or database programs) for comparison between historic and current information. You can now track the changes in volume of Anilox rolls and monitor their condition. Having a graphical history of wear on the anilox rolls will allow you to plan, financially and in production, for roll replacement or refurbishment. AniCAM HD™ is very portable, therefore measurements can be taken in the press room, the plate room or in the anilox storage area making it a very practical all round tool for all print departments.