Anderson & Vreeland (A&V) has established itself as a leader in the flexographic printing industry, setting high standards for print quality, durability, and cost efficiency. Their AVantage™ Liquid Photopolymer line provides high-performance solutions tailored to the needs of various flexographic printing applications, from molding to stamping and multi-wall bag production.

But what sets AVantage™ apart isn’t just its quality — it’s A&V’s strategic move to develop and manufacture these products as an OEM (Original Equipment Manufacturer) rather than as a distributor, giving them greater control over product design, innovation, and customer satisfaction.

A&V’s Strategic Move: Leading the Market as an OEM in Liquid Photopolymer Solutions

“A&V leadership made the decision to get into this marketplace more from an OEM position, as opposed to a distributor in an effort to differentiate us from our competitors,” says Larry Dingman, AVantage Business Manager. “This was based upon the needs of our customers in terms of diversification or additional choices and options in OEMs of liquid photopolymer resins and consumables. As a result of this direction, we have firmly positioned ourselves as a leader in the fulfillment of this and many other products and services to the flexo printing industry.”

In response to the needs of flexographic printers, A&V launched four core AVantage™ Liquid Photopolymer products, each crafted to deliver optimal elasticity, resilience, hardness, and ink transfer.

1. AVMaster™ Liquid Photopolymer: The Solution for Molding Applications

The AVMaster liquid photopolymer plate is designed specifically for molding applications, ensuring improved print consistency and quality. With an 80/90 Shore A durometer rating, this durable plate is engineered to meet the demanding needs of the molding industry.

Advantages:

- Highly resilient and durable

- Excellent for fine detail work

- Low tack for ease of handling

- UV, heat, and humidity stability

- Environmentally friendly formulation

These qualities make AVMaster a top choice for printers seeking longevity and reduced environmental impact without compromising print quality.

2. AVBag™ Liquid Photopolymer: Ideal for Multi-Wall and Poly Bags

When it comes to multi-wall bag and poly bag printing, AVBag is the industry’s answer for superior print quality on both paper and poly surfaces. This 55 Shore A durometer plate is reliable, economical, and can be prepared in less than an hour, making it highly efficient for printers.

Advantages:

- Compatible with most water- and glycol-based inks

- Durable for long-lasting use

- Quick turnaround time

- Economical, with easy storage and mounting

3. AVStamp™ Liquid Photopolymer: Designed for Craft, Hobby & Scrapbook Markets

For high-resolution stamping needs, AVStamp offers UV stability, meeting the stringent demands of the craft, hobby, and scrapbook markets. With a 50 Shore A durometer rating, this liquid photopolymer is perfect for delivering crisp and consistent ink transfer.

Advantages:

- Suitable for most water- and glycol-based inks

- Non-yellowing for prolonged use

- Wide imaging latitude

- Environmentally friendly and medium tack

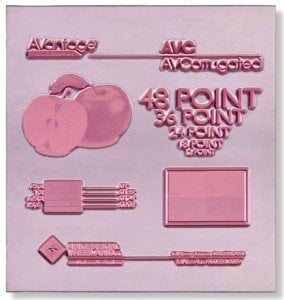

4. AVCorrugated™ Liquid Photopolymer: Perfect for Corrugated Applications

AVCorrugated is a flexible, durable option designed for corrugated printing applications. Available in both Clear and Red with a 34 Shore A durometer rating, this plate delivers impressive ink transfer and clean running, making it ideal for high-volume, corrugated packaging work.

Advantages:

- Low tack for clean press runs

- Durable for extended use

- Suitable with most water- and glycol-based inks

- Excellent ink transfer properties

Supporting Products for the AVantage™ Liquid Photopolymer Line

To complement the AVantage™ liquid photopolymer plates, A&V also offers a range of ancillary items. These include matte and clear cover films, washout solutions, plate substrates, post-exposure salts, liquid developers, defoamers, and imaging film. These additional resources help printers achieve an even higher level of precision and quality control across applications.

Why Choose AVantage™ Liquid Photopolymer?

Anderson & Vreeland’s AVantage™ Liquid Photopolymer product line reflects the company’s commitment to innovation and customer-focused solutions. By taking on an OEM role, A&V has expanded its flexibility and ability to respond directly to industry demands, allowing the company to deliver more specialized products to meet unique printing needs. Whether you’re looking for a solution in molding, multi-wall bag production, crafting, or corrugated printing, the AVantage™ line provides dependable, high-quality options tailored to the specific demands of each sector.

AVantage™ Liquid Photopolymer products give flexographic printers an edge in achieving vibrant, resilient, and precise prints, elevating the overall quality and efficiency of their work. With a focus on customer needs and a commitment to innovation, A&V’s photopolymer line is setting the standard for the future of flexographic printing.