You’ve probably heard it a thousand times—your anilox rolls are the heart of your flexo press. That’s absolutely true. But there are smaller, less costly parts that, while not as prominent, still have a direct impact on every label, flexible package, folding carton, or corrugated container you produce. These parts are flexo printing consumables, and they’re meant to be replaced regularly. The question is, are you selecting the right ones and managing them carefully? Like many things in flexo printing, the details matter.

No One-Size-Fits-All Approach to Flexo Printing Consumables

Two flexo shops I work with, one in the southwest and another in California, both run similar volumes of pressure-sensitive labels but use different strategies when it comes to flexo printing consumables. The California shop specializes in long runs that last all day or longer, while the southwest shop completes several short runs each day.

The long-run shop invests in the best doctor blades, end seals, and stickyback tape available so they don’t have to stop their presses. One job may run thousands of feet and occupy a press for days, but it runs seamlessly unless a fresh roll of substrate is needed. Conversely, the southwest shop opts for more affordable blades, seals, and stickyback tape, ensuring new flexo printing consumables are always on hand for each job. Both strategies work, tailored to their specific production styles.

The Importance of Matching Flexo Printing Consumables to Your Workflow

Neither of these shop owners worries about downtime because they’ve matched their flexo printing consumables to the types of work they run. Unfortunately, many shop owners focus too heavily on minimizing consumable costs rather than choosing products that yield the best results.

The Cost of Saving a Dollar on Flexo Printing Consumables

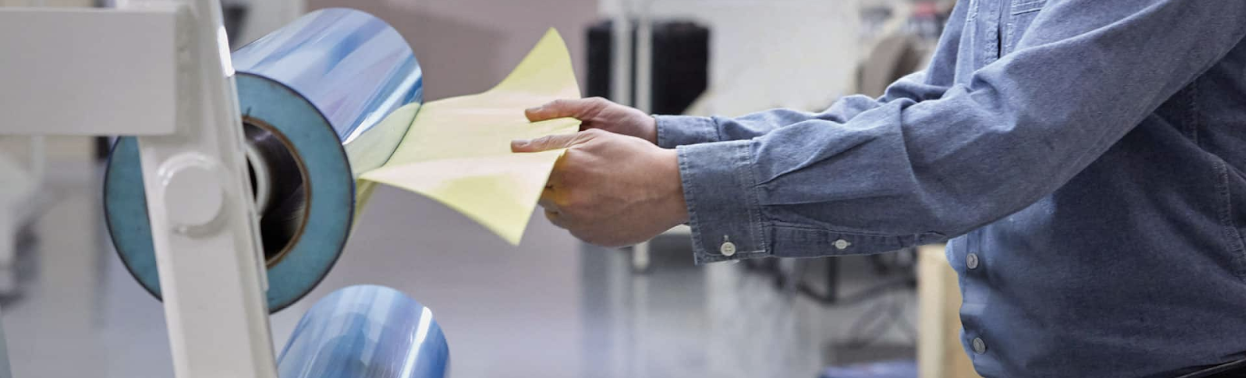

Take stickyback tape, for example. Tape selection impacts the way a plate and substrate print, and this is just one layer of the decision-making process. After choosing a tape based on thickness and compression characteristics, there are cost-saving options—but they come with risks. One common problem is the leading edge of the tape lifting, causing the plate to detach from the cylinder. You can patch this with plate edge tape or glue stick—assuming you catch it in time before the plate peels off entirely.

However, a higher-quality tape—which might cost an extra dollar per station—can prevent these issues altogether. When you consider the downtime associated with stopping the press, fixing the problem, and restarting it, along with wasted substrate, the savings from using cheaper flexo printing consumables disappear quickly.

The 20% Difference in Flexo Printing Consumables

By closely monitoring the costs associated with different flexo printing consumables, it’s clear that higher-quality options often save more in the long run. The additional costs are offset by increased reliability, consistency, and reduced downtime. Many printers who track their costs over a full year find they save up to 20% by using better-quality consumables.

Look at the strategies used by the two printers mentioned earlier. Both have optimized their flexo printing consumables—whether for long runs or frequent short runs—to maximize efficiency and minimize downtime.

Anderson & Vreeland: Your Partner for Flexo Printing Consumables

At Anderson & Vreeland, we act like the code reader for your car—helping you diagnose whether the issue is a quick, cost-effective fix or something requiring more in-depth attention. By working closely with your business and production teams, we help you choose the flexo printing consumables that align with your unique needs.

Ready to optimize your flexo production process? Contact us at 866-282-7697, email info@andersonvreeland.com, or reach out to a technical sales rep. Let’s help you develop a consumable strategy that keeps your press running efficiently and your customers coming back for more.