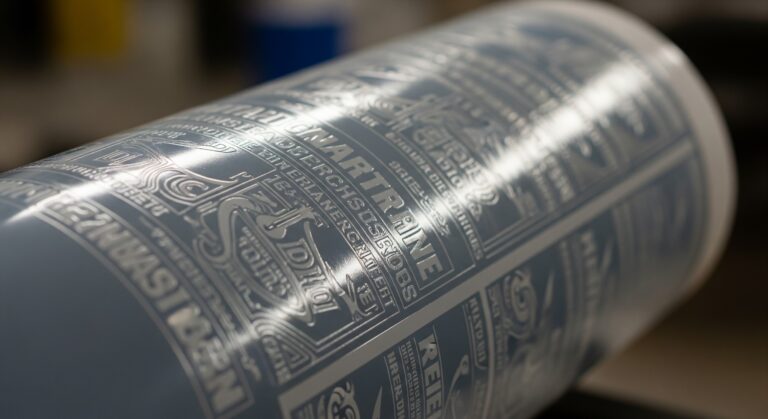

The flexographic printing equipment that professional printers and converters choose for every step in their production flow directly impacts their business’s overall success. Choosing the right equipment streamlines the entire printing process, contributes significantly to your ROI, and saves time and resources. However, selecting the best fit for your flexographic printing equipment needs is not a quick and easy task. It involves careful consideration and should be thoughtfully planned and agreed upon by your entire team.

Key Factors to Consider When Purchasing Flexographic Printing Equipment

Several important details to consider when selecting your machines include functionality, quality, specifications, and capacity. Your equipment needs to match the demands of your work accurately. Here are five common mistakes to avoid when purchasing flexographic printing equipment.

1. Prioritizing Unnecessary Features and Functions

Most flexographic printing equipment today offers modern and technological features that can be enticing. However, surplus features such as advanced automation, rapid printing, and efficient drive systems not only increase prices but can distract from the machine’s primary functionality. Before committing to add-ons, ask yourself: How do these features improve the efficiency of my workflow? What value do they add to production?

Choosing equipment with features you won’t fully utilize can set you back financially and hinder operational efficiency. Always ensure the investment fits your budget, meets current needs, and aligns with long-term goals.

2. Buying a Bargain Machine

While being savvy with spending is important, selecting flexographic printing equipment based solely on price can lead to long-term financial setbacks. Bargain machines with low-quality components will likely require frequent repairs and won’t be able to keep up with your workflow, delaying productivity and reducing ROI.

Performance and quality should be the primary factors when choosing flexographic printing equipment. If you find a low-cost machine, ensure it meets your standards and request a test to verify its suitability for your business needs. Reliable vendors often offer financing options, allowing you to make the best decision for your company.

3. Choosing Brand Over Functionality

Brand loyalty is admirable but shouldn’t compromise your standards when selecting flexographic printing equipment. Not every brand consistently maintains the highest safety measures or keeps up with industry innovations. A brand that was ideal a decade ago might not be the best fit today.

The best way to avoid bias is to select a vendor that offers a wide range of flexographic printing solutions across multiple brands. This ensures you get the most appropriate flexographic printing equipment at the best price, based on functionality and capacity rather than brand loyalty.

4. Neglecting to Confirm Aftersales Services

Aftersales service is a critical factor in ensuring your flexographic printing equipment remains functional and efficient over time. Services such as regular maintenance, part replacements, on-site support, and troubleshooting are essential for maintaining the longevity of your equipment.

Before purchasing, always confirm the aftersales services provided and agree on specific service levels. To avoid future disputes, outline the details in a contract, including troubleshooting support, training materials, and customer feedback systems.

5. Putting New Equipment into Service Too Soon

One common mistake printers make is rushing to use newly purchased flexographic printing equipment without sufficient training. Flexographic printing machines are often more complex than standard technologies, and improper handling can lead to accidents, injuries, or equipment damage.

Take the time to train employees on operating the new machine, ensuring they understand its functionality and where it fits in the production workflow. Proper training will reduce errors, lower costs, and minimize waste.

Improve Productivity with the Right Flexographic Printing Equipment

Selecting the right flexographic printing equipment is crucial to the future success of your printing production. The right equipment will streamline operations, enhance productivity, and contribute to consistent business growth. By avoiding the mistakes listed above, your company can expect a higher ROI and greater operational efficiency.

If you have questions about the next steps, Anderson & Vreeland can help. We offer a wide range of pre-press, plateroom, and pressroom equipment solutions. Contact our team to start planning your flexographic printing equipment strategy today.