When Vice President Jason Hynes and the team at ATL Corp. in Menomonee Falls, WI, decided it was time to elevate their flexographic printing business, they knew exactly what they needed: the latest in digital platemaking.

Founded in 1954, ATL started as a humble printing shop and has since grown into a full-service printing and material converting company. Recently, the focus has shifted more towards converting services like die cutting and laminating. However, to truly advance their flexographic label printing, investing in a digital platemaking system was essential.

Finding A&V’s Digital Platemaking System

Despite having a solid platemaking system, ATL struggled to meet the high-quality demands of sophisticated customers. “The main issue was achieving a higher quality level,” says Mr. Hynes. Often, they had to outsource flexo plate production, leading to increased costs and longer lead times.

While exploring options to upgrade their system, ATL was approached by Anderson & Vreeland. Although ATL had previously only purchased basic consumables from A&V, this time, they recognized a greater potential. As Mr. Hynes puts it, they “opened the cupboard” and discovered the competitive edge a deeper relationship with A&V could provide. After thorough research and due diligence, ATL chose A&V, whose comprehensive portfolio met their specific needs for digital platemaking perfectly.

Fast Response and In-Depth Support for Digital Platemaking

A critical factor in ATL’s decision to partner with A&V was its fast response and comprehensive support. During ATL’s research phase, A&V was quick to provide quotes and schedule follow-up meetings. Within a week of the initial inquiry, A&V’s Digital Business Analyst Jeff Skolnik, members of the A&V Business Solutions Group, and James Van Buskirk of XSYS met with ATL to outline how A&V could support their new digital platemaking system. Additionally, when ATL’s Pre-Press & Art Director, Carissa Tesch, needed help designing their new plate room, A&V delivered detailed plans within 48 hours. This level of responsiveness made ATL realize they had a true partner in A&V.

The ongoing support and education from A&V further solidified ATL’s decision. As a global printing, converting, and contract manufacturing company, ATL needed a partner who could guide them to the best technology in digital platemaking. “We were seeking a partner that could bring all that together – from art to part – and that’s exactly what A&V did,” says Jason Hynes. A&V’s expertise and extensive digital portfolio provided unparalleled support and education, acting as both educator and consultant to guide ATL toward optimal solutions. “What A&V continues to do is educate and provide the knowledge and solutions,” says Ms. Tesch. “And I think this will be A&V’s key to continued growth with us.”

Taking ATL to the Next Level

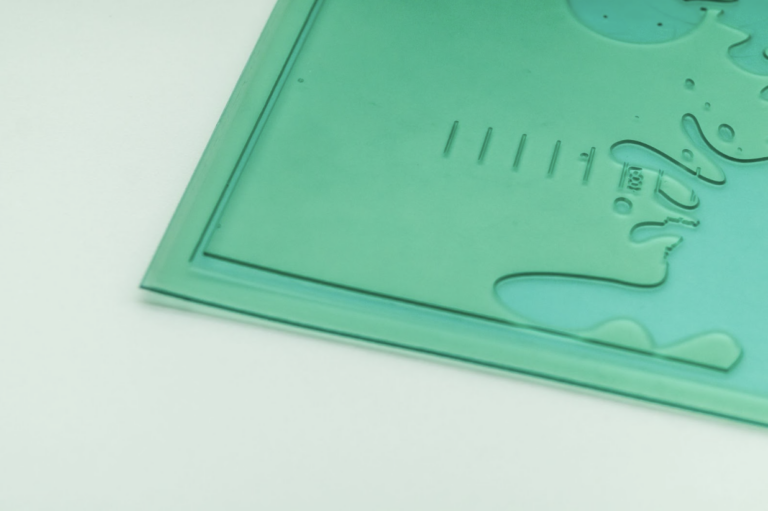

Within six months, ATL was equipped with a new ThermoflexX Digital Platemaker, known for its industry-leading 5,080 dpi resolution, along with Front-End Software for preparing platemaking files, an XSYS nyloflex® Xpress Thermal Processing System, an Ovit plate washer, and other necessary equipment.

The ATL team immediately noticed the higher resolution of prints from their presses. With ThermoflexX imaging plates at 5,080 dpi and 150 lpi resolution, their presses produced clearer images, sharper text, and higher line rulings. This upgrade allowed ATL to offer significantly improved print quality to their customers by enhancing their existing presses with better front-end and digital platemaking systems.

Internally, ATL experienced quicker plate production times. The ThermoflexX system’s automatic plate loading and auto-feed capabilities cut plate production time in half, reducing human handling and making the process easily scalable – a key factor in ATL’s growth.

The faster, more efficient plate making process allowed ATL to increase its press output, complete more jobs per shift, reduce customer turnaround times, and offer competitive pricing. But beyond pricing, customers valued the enhanced print quality. “Our customers really value print quality. We’ve always been a quality-focused company, and this new equipment really brought us to a new level,” says Mr. Hynes. “This plate making system will help us grow into other markets, no question about it.”

A Deeper Partnership

ATL’s partnership with A&V is just beginning. ATL plans to further strengthen its relationship with A&V as they add another new flexographic printing press to support their business growth. “We are excited to be a part of ATL’s growth,” says Jeff Skolnik. “This long-term partnership will help solidify ATL’s strength and visibility within the industry. Providing advanced technology from our world-class partners and serving ATL with our vast resources of support is what A&V is all about.”

ATL Corp’s journey with digital platemaking is a testament to the transformative power of the right technology and a supportive partnership. With A&V by their side, ATL is poised for continued success and growth in the flexographic printing industry.