In the fast-paced world of packaging printing, some companies push the boundaries with cutting-edge software and equipment, while others take a more measured approach. Both strategies can deliver impressive results for printers and their customers. Allen-Bailey Tag & Label, Inc., a 107-year-old company in Caledonia, New York, is a prime example of how thoughtful innovation, particularly in plate making technology, can drive success.

Embracing Measured Innovation with Plate Making Technology

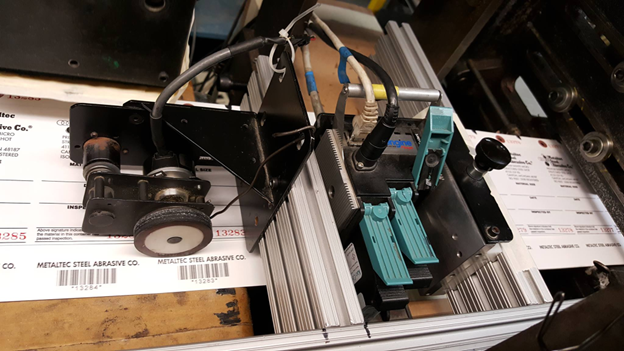

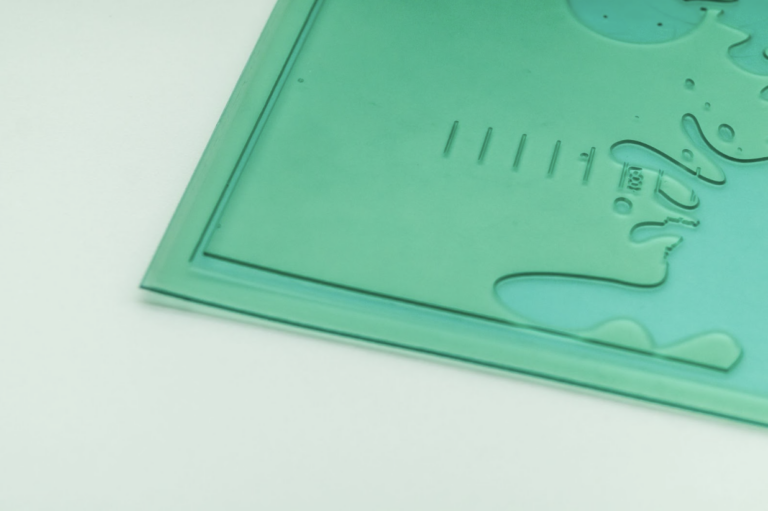

Allen-Bailey Tag & Label, a historic firm just outside Rochester, NY, has long been known for its steady growth and careful adoption of new technologies. Their latest advancement in plate making technology is the acquisition of the XSYS ThermoflexX 20 platesetter, a move that enhances the quality of their printing plates, reduces production costs, and boosts efficiency by cutting out time-consuming steps. This investment in state-of-the-art plate making technology positions the company to meet growing customer demands.

From Outsourcing to Insourcing: How Plate Making Technology Changed the Game

For over three decades, Allen-Bailey operated independently, outsourcing a portion of its printing plates. However, recognizing the opportunities presented by a growing economy, Richard G. Phelps, Owner & Director of Marketing, saw the need for a shift in strategy. “With the economy on the rise and our customers expanding, we knew it was time to adopt advanced plate making technology to better serve our clients,” said Phelps. The new XSYS ThermoflexX 20 enables Allen-Bailey to produce plates in-house, giving them greater control over quality and production timelines.

Defining the Challenge: Selecting the Right Plate Making Technology

To choose the optimal plate making technology for their needs, Allen-Bailey partnered with Anderson & Vreeland, a leader in printing solutions. Their Digital Business Analyst & Account Manager worked closely with Phelps to assess the company’s goals. After careful analysis, the XSYS ThermoflexX 20 was identified as the ideal solution, offering seamless integration of upgraded plate making, advanced hardware, and a modern workflow. This new plate making technology will meet Allen-Bailey’s current needs and position them for future growth.

Comprehensive Implementation of New Plate Making Technology

As with any advanced system, integrating new plate making technology can be complex. Anderson & Vreeland’s Technologies Team, alongside XSYS, collaborated with Allen-Bailey’s pre-press staff to ensure smooth implementation. The system became fully operational in late 2017, and the A&V Technologies Team continues to provide support, training, and refinements to ensure optimal productivity from every component of the new plate making technology.

“It took time for us to fully appreciate all the benefits this advanced plate making technology offers,” Phelps shared. “The support we received from Anderson & Vreeland was crucial in making sure the new equipment fit our needs and was smoothly integrated into our operations.”

The Measured Approach to Plate Making Technology

Allen-Bailey’s decision to embrace plate making technology through the XSYS ThermoflexX 20 has strengthened its ability to serve its customers and compete in a growing market. By adopting a measured approach to innovation, the company continues to build on its legacy of quality and reliability, ensuring its position as a leader in the printing industry for years to come.