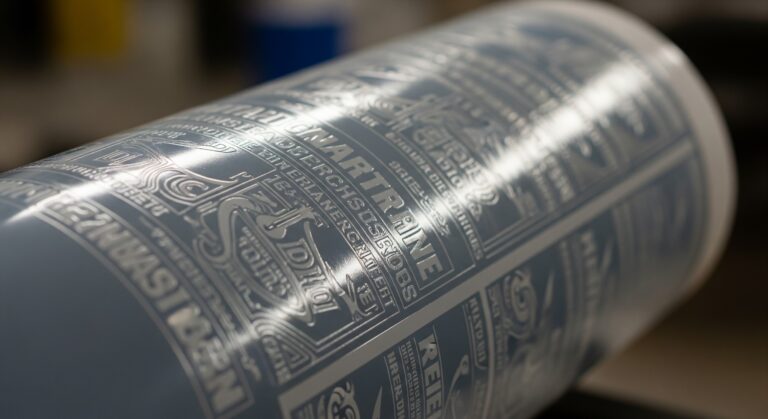

You probably don’t know the answer offhand, but what do you really know about the condition of your anilox rolls? Pull any five randomly from your storage racks and take a close look to get a handle on this. Is the ceramic coating getting a bit thin? Is there any scoring? Are the cells holding the correct amount of ink, or are they filling with dried ink? Are your press operators doing any extra work or making adjustments to the press to ensure the tags, labels, and packages you print are ones your current clients will accept, and that will make new customers happy?

These are common concerns that make anilox rolls—the heart of your press—worthy of anilox roll evaluations so you can make informed decisions about cleaning, refurbishing, or replacement. There are a couple of ways to do a complete evaluation, from old-school visual inspection and manual measurements to the latest digital techniques.

The Need for Anilox Roll Evaluations

Many Anderson & Vreeland customers are asking for comprehensive digital audits of their anilox rolls to assess their condition accurately. They have found that an Anicam Audit helps identify and remove bad, old, or worn anilox rolls from inventory before they cause problems and delays on press.

“Anilox roll evaluations give customers access to a technology with a level of detail that helps them make more informed decisions regarding their anilox maintenance,” explains Martin Schofield, Anderson & Vreeland, ULC Account Manager.

What is an Anicam Audit?

The Anicam is the name of a device made by one of our partners, Troika Systems. The Anicam is a specialized digital camera that takes a deep dive into your anilox rolls, looking for scoring, measuring cell depth, and any other irregularities that can cause problems on press.

Designed to be mounted on any size or type of anilox roll, the Anicam does a close analysis and measurement of a roll, providing a detailed view of anything that can cause a problem. For instance, if dried ink has reduced cell volume by 25% in a third of a roll’s cells, it’s a pretty good indication that that roll may cause some problems on press. It’s probably better to know this in advance.

Benefits of Anilox Roll Evaluations

Dave Dixon, Plant Manager at Jones Packaging in London, Ontario, started using the A&V Canada Anilox Audit program last year. He says the benefits showed up quickly.

“The Anicam Anilox Audit program allows us to identify problematic anilox rolls before they go onto the press and cause a myriad of different issues,” says Dixon.

“Customers have been very pleased with the Anicam audits,” adds Schofield. “The reports are easy to read and offer much more detailed information than manual anilox inspection methods.”

Color-Coded Reports for Better Decision Making

The Anicam describes trouble spots with a full-color report showing each roll’s condition before any problems appear on press. Printers using the audit typically schedule the evaluation on rolls not being used so they can be recoated or replaced before they are needed. It is not uncommon for Canadian printers to take advantage of the audit to incorporate the info it provides into an ongoing monitoring program that helps ensure the hearts of their presses are always in optimal condition.

“The color-coded (green/yellow/red) identifier on each report tells us at a glance the condition of all of our rolls, so we can better prepare for upcoming anilox replacement and budget accordingly,” says Dixon.

Growing Demand for Anilox Roll Evaluations

Demand for anilox roll evaluations has increased as word of the program has spread across Canada. “We suspected the program would be popular but may have underestimated the need,” says Sean Sawa, Director of Sales for Anderson & Vreeland Canada. “We are considering purchasing another Anicam to meet demand. For our clients, detailed knowledge of their anilox roll quality can significantly reduce downtime by ensuring that less-than-optimum anilox rolls never make it onto the press.”

Final Thoughts

In the fast-paced world of flexographic printing, anilox roll evaluations are essential for maintaining the quality and efficiency of your printing operations. By utilizing advanced technologies like the Anicam, printers can proactively manage their anilox rolls, ensuring that their presses run smoothly and effectively.

For more information on how A&V can enhance your printing process, contact us today.