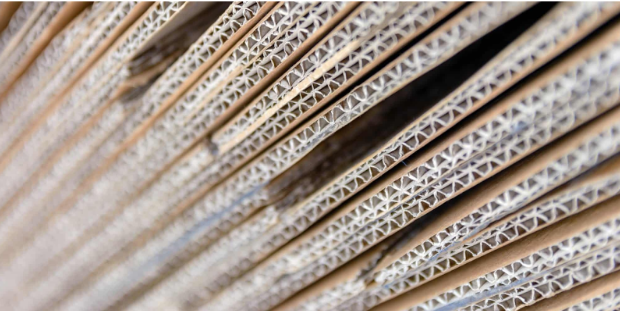

In any given week, news outlets frequently cover Amazon’s influence on the economy, infrastructure, and local real estate markets. However, there’s one crucial aspect that often goes unnoticed: Amazon’s profound impact on corrugated printing and packaging. Corrugated containers, or cardboard, play an essential role in Amazon’s massive logistics network, ensuring products are shipped economically and reliably globally.

Corrugated Printing: The Unsung Hero of E-commerce

Corrugated packaging, commonly used to ship a wide variety of Amazon’s products, is practical and efficient. These containers range in size from those small enough for a single hardcover book to massive boxes capable of holding commercial appliances. The majority of Amazon’s packages are shipped in corrugated boxes featuring the iconic two-color Amazon logo, printed using advanced corrugated printing processes.

However, Amazon isn’t the only company that relies on corrugated packaging. Countless brands across various industries use similar methods to print logos, handling instructions, and product information onto corrugated sheets. This is where Anderson & Vreeland plays a significant role, providing corrugated printing solutions to converters, trade shops, and service bureaus

Anderson & Vreeland: Leaders in Corrugated Printing

Anderson & Vreeland (A&V) offers a wide range of supplies and technologies that support the corrugated packaging industry. These include:

- AVantage Liquid Photopolymers: Essential for creating durable and high-quality printing plates used in corrugated printing.

- XSYS Corrugated Printing Plates: Robust plates designed to handle the rigors of printing on corrugated surfaces.

- Patchplanner Software from Hybrid Software: A valuable tool for optimizing plate use and enhancing the efficiency of the printing process.

- Thermal and Digital Imagesetters from Exile and XSYS: Innovative imaging solutions that provide high-resolution printing capabilities.

- Tapes and Backing Materials: From trusted brands like 3M, Adheso, and Tesa, ensuring precise mounting and secure attachment of plates to printing equipment.

These materials are supported by A&V’s network of eight strategically located warehouses across the U.S. In addition, A&V boasts a team of specialists who focus exclusively on the corrugated printing market, understanding the unique needs and challenges that come with it.

The Evolving Market for Corrugated Printing

Corrugated printing is no longer just a simple or niche process. The increasing demand for branded, customized packaging is driving innovation within the sector. As companies strive to make their packages stand out on the doorstep, the printing technology required to meet these needs is becoming more advanced and specialized.

Anderson & Vreeland has responded to these market demands by offering state-of-the-art solutions that improve the efficiency and quality of corrugated printing. Their range of products and services ensures that brands can achieve the desired print quality on packages of all shapes and sizes.

Final Thoughts

In the rapidly growing world of e-commerce, corrugated packaging has become an essential component of the supply chain. With major players like Amazon setting the pace, the demand for high-quality corrugated printing has never been greater. Anderson & Vreeland’s range of products and expertise ensures that trade shops and converters have the tools they need to meet this demand, delivering reliable and consistent results.

For businesses involved in corrugated printing, partnering with Anderson & Vreeland means access to cutting-edge technology, specialized support, and a wealth of industry knowledge—all designed to help them succeed in this fast-paced, ever-evolving market.