As the global demand for environmentally responsible practices continues to grow, the printing industry is embracing innovative solutions to reduce its environmental impact. Flexographic printing, a cornerstone of modern packaging and labeling, is leading the charge with sustainable printing technologies that balance high-quality output with eco-conscious processes.

This blog explores the future of sustainable printing, highlighting advancements like water-wash solutions and eco-friendly plates and how Anderson & Vreeland supports flexographic printers in adopting these green innovations.

What is Sustainable Printing?

Sustainable printing refers to practices and technologies that minimize waste, reduce energy consumption, and employ eco-friendly materials. In flexographic printing this means using water-based inks, recyclable substrates, energy-efficient equipment, and innovative plate-making technologies that reduce harmful emissions. By adopting sustainable printing methods, businesses can lower their carbon footprint while meeting the growing consumer demand for environmentally friendly products.

Advancements in Sustainable Printing for Flexographic Printers

The flexographic printing industry has seen significant strides in sustainability through innovative products and processes. Below are some of the key advancements driving this transformation:

1. Water-Wash Solutions

Water-washable plates are revolutionizing sustainable printing by eliminating the need for harmful solvents during plate processing. Products like Toyobo’s Cosmolight plates are at the forefront of this innovation. These plates use tap water and mild detergents instead of toxic chemicals, significantly reducing volatile organic compound (VOC) emissions and hazardous waste.

- Cosmolight Plates: Distributed by Anderson & Vreeland, these photopolymer plates can reduce emissions by up to 70% compared to traditional solvent-based plates. They offer excellent durability and print quality while ensuring a safer work environment.

2. Eco-Friendly Plate Technologies

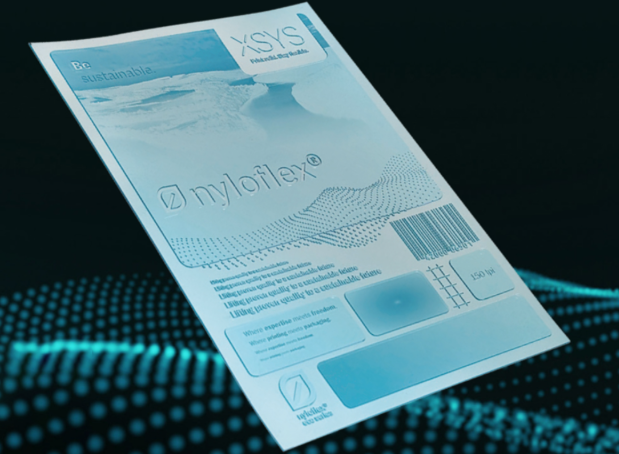

XSYS has introduced the nyloflex® eco plate series, which incorporates renewable raw materials into its formulation. These plates process 20% faster than standard options, saving time and energy while maintaining high print quality. The nyloflex® eco plates are ideal for corrugated post-print applications and demonstrate how sustainable materials can enhance productivity without compromising performance.

3. Energy-Efficient Inks and Drying Systems

Flexographic printers are increasingly adopting water-based inks and UV-curable inks as part of their sustainable printing strategies. Water-based inks release fewer VOCs into the atmosphere, improving air quality and reducing environmental impact. Similarly, UV-curable inks shorten drying times and consume less energy compared to traditional drying methods, making them both cost-effective and eco-friendly.

4. Sustainable Substrates

The use of biodegradable and recyclable materials is another significant advancement in sustainable printing. Flexographic printers can now work with substrates like plant-based films and recycled paper, which decompose naturally or can be reused in new production cycles. These materials align with consumer preferences for sustainable packaging solutions.

5. Closed-Loop Systems

To further reduce waste, many flexographic printers are implementing closed-loop systems that recycle water, ink, and solvents during the printing process. These systems not only conserve resources but also lower operational costs by minimizing material wastage.

The Role of Anderson & Vreeland in Sustainable Printing

As a trusted partner in flexographic printing, Anderson & Vreeland is committed to advancing sustainable printing solutions through innovative products and expert support. The company distributes cutting-edge technologies like Cosmolight plates and XSYS nyloflex® eco plates while offering comprehensive guidance to help printers transition to greener practices.

Key Contributions:

- Product Innovation: Anderson & Vreeland provides access to state-of-the-art water-washable plate technologies that eliminate hazardous chemicals from the plate-making process.

- Sustainability Initiatives: The company actively promotes sustainability through programs like solvent recycling and waste reduction strategies.

- Expert Support: With decades of experience in flexographic printing, Anderson & Vreeland offers tailored solutions to help businesses adopt sustainable practices without compromising efficiency or quality.

Why Sustainable Printing Matters

Adopting sustainable printing practices is no longer optional—it’s a business imperative. Consumers are increasingly prioritizing brands that demonstrate environmental responsibility. According to recent studies, 66% of global shoppers are willing to pay more for eco-friendly products. By transitioning to sustainable printing methods, businesses can not only reduce their environmental impact but also strengthen their brand reputation and appeal to eco-conscious customers.

The Future of Sustainable Printing

The future of sustainable printing lies in continued innovation across all aspects of the flexographic process:

- Improved Plate Technologies: Advancements in water-washable plates will further reduce VOC emissions and processing times.

- Energy-Efficient Equipment: New drying systems and presses will consume less energy while maintaining high productivity.

- Circular Economy Practices: Recycling programs for substrates, inks, and solvents will become standard across the industry.

With companies like Anderson & Vreeland, flexographic printers have access to the tools they need to embrace these changes effectively.

Sustainability with Anderson & Vreeland

Sustainable printing is transforming the flexographic industry by introducing eco-friendly solutions that deliver both environmental benefits and operational efficiencies. Innovations like water-washable plates, renewable substrates, and energy-efficient inks are paving the way for a greener future in packaging and labeling.

Anderson & Vreeland’s commitment to sustainability ensures that flexographic printers have access to cutting-edge technologies like Cosmolight plates and XSYS nyloflex® eco plates. By partnering with experts in sustainable printing, businesses can stay ahead of industry trends while contributing positively to environmental conservation.

Embrace sustainable printing today—because a greener future starts with smarter choices in flexography! Contact us today.