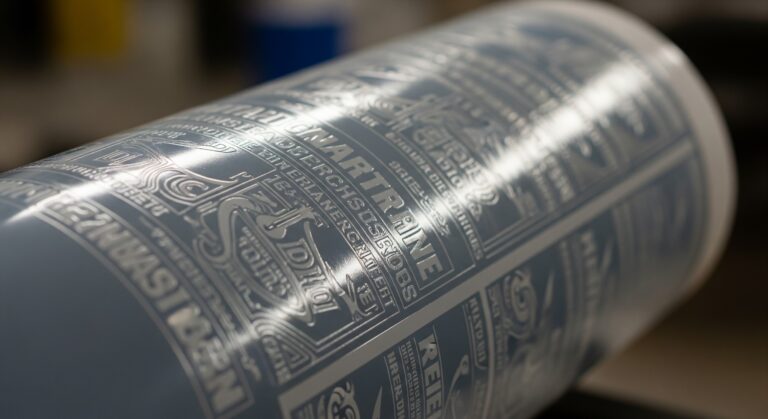

Ink pumps are an essential yet often overlooked component in the flexographic printing process. These devices play a crucial role in ensuring consistent ink flow and quality throughout print runs. Let’s explore the various types of ink pumps and their numerous benefits for flexographic printers.

Types of Ink Pumps

There are several types of ink pumps available for the flexo industry, each designed to meet specific printing needs:

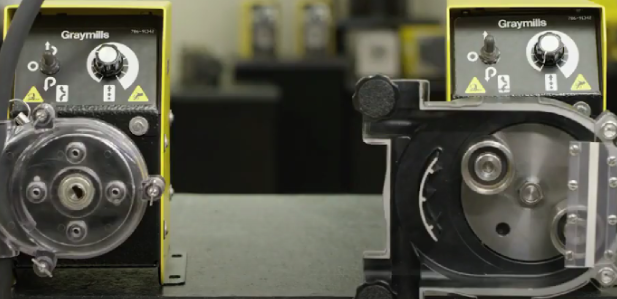

- Peristaltic Ink Pumps: Designed for handling abrasive, corrosive, and shear-sensitive solutions, these pumps are ideal for specialized inks.

- Double Diaphragm Ink Pumps: These versatile pumps can be used with a wide range of inks, varnishes, coatings, adhesives, and laminates.

- Accessories: Various filters, mixers, and other accessories complement these ink pumps, ensuring optimal performance and longevity.

- Magnetic Ink Filters: In a smooth stainless steel casing and 10x the pulling power of a standard magnet, megaMAG™ can attract metal particles from within the filter body or ink tank.

Benefits of Ink Pumps in Flexographic Printing

Improved Ink Consistency

Ink pumps ensure a steady and consistent flow of ink to the printing plates, resulting in uniform print quality throughout the run. This consistency is crucial for maintaining color accuracy and overall print quality.

Enhanced Productivity

By automating the ink delivery process, ink pumps significantly reduce downtime associated with manual ink replenishment. This automation allows for longer, uninterrupted print runs, boosting overall productivity.

Cost-Effective Solution

While the initial investment in ink pumps may seem significant, they offer long-term cost savings. By reducing ink waste and improving efficiency, ink pumps can lead to substantial savings over time.

Versatility

Modern ink pumps, like those offered by Powerwise, are designed to handle a wide range of inks and coatings. This versatility allows printers to use the same pump for various jobs, reducing the need for multiple specialized equipment.

Easy Installation and Maintenance

Companies like Powerwise offer ink pumps designed for easy installation and maintenance. Their “one-install, inclusive solution” approach means that printers can quickly set up and start using these pumps without the need for additional components.

Powerwise: A Leader in Ink Pump Technology

Powerwise, a partner of Anderson & Vreeland, has been at the forefront of ink pump technology for over 60 years. Their commitment to customer satisfaction and ability to create custom solutions sets them apart in the industry.

Customer-Oriented Approach

Despite being a small company, Powerwise prioritizes customer satisfaction. They offer follow-up services to ensure customers are happy with their purchases and provide quick shipping for urgent needs.

Custom Solutions

Powerwise’s in-house designers and local manufacturers allow them to create custom pieces for customers with specific needs. This flexibility enables them to tackle unique projects that larger companies might be unable to accommodate.

Final Thoughts

Ink pumps are a vital component in modern flexographic printing operations. By ensuring consistent ink flow, improving productivity, and offering cost-effective solutions, these devices have become indispensable tools for printers looking to enhance their efficiency and print quality. With companies like Powerwise continually innovating in this space, the future of ink pump technology looks promising for the flexographic printing industry.