In flexographic printing, the efficiency and quality of plate making systems can significantly impact production. Many narrow web shops still rely on old Kelleigh processing units that are barely holding on.

These machines, once industry staples, are now out of business, lack technical support, and are literally being held together by duct tape. With brushes wearing down and diminishing quality, these solvent processors are no longer designed to handle the new technology of digital plates. If your shop is still using Kelleigh units, it’s time to consider upgrading flexo plate making systems for improved quality and future-proofing your operations.

Upgrading Flexo Plate Making Systems From Old Kelleigh Processing Units

Kelleigh units, large and cumbersome, dominate many narrow web environments but come with increasing headaches. Without LED exposure capability, which is the future of flexo plate processing, these systems lag behind modern standards.

Additionally:

- No longer supported technically

- Quality deteriorates as parts wear out

- Not built for digital plate technology

- Inefficient, slow processing times

Upgrading flexo plate making systems will eliminate the constant worry of when your unit will finally break down, saving downtime and lost productivity.

Modern Solvent Plate Making Systems: Vianord EVO Family

If you prefer to continue with solvent-based processing, consider the Vianord EVO family of machines.

They represent a leap forward with:

- Enhanced plate quality

- Significant reduction in plate processing times

- Inclusion of LED exposure for sharper and more consistent plates

These advancements make Vianord a smart choice for shops wanting to maintain solvent processing but upgrade to current technology. You can learn more about their LED exposure capabilities and how they revolutionize flexo prepress here.

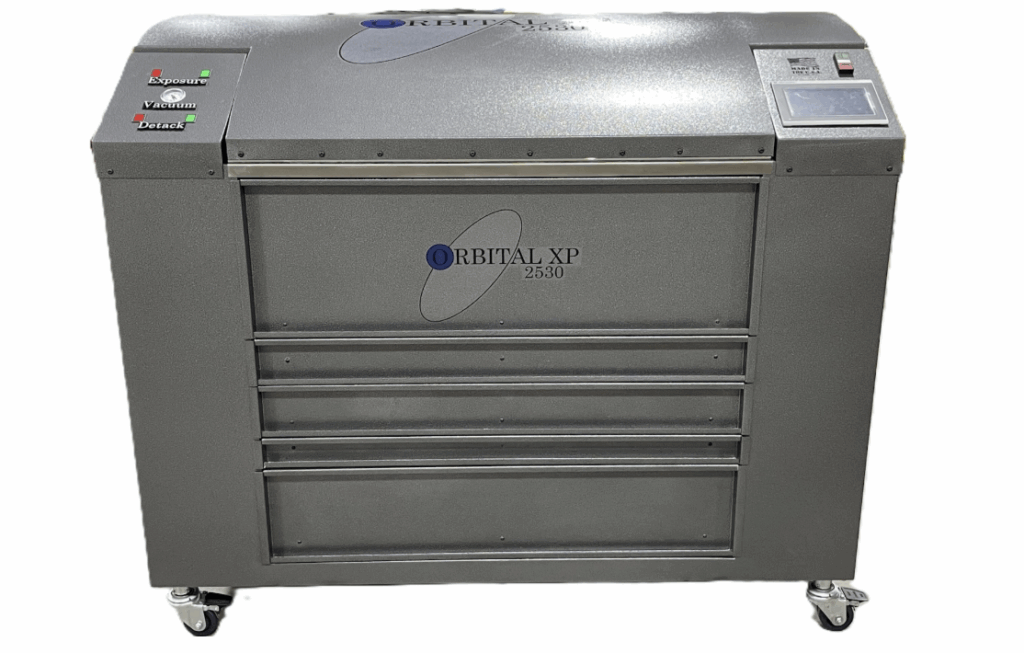

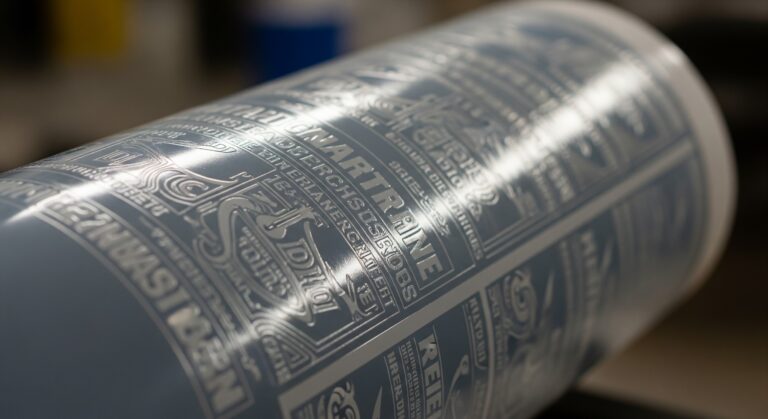

Switch to Sustainable Water Wash Plate Making with Orbital XP and Toyobo Plates

For those ready to transition away from solvent processing, water wash plate making is a sustainable and efficient alternative. With systems like Orbital XP designed to process Toyobo plates, you can reduce your platemaking process from three hours to just one.

Benefits include:

- Lower environmental impact with water wash technology

- Flat top water wash plates offer better ink transfer and print quality compared to solvent plates

- Smaller machine footprint—Orbital XP units are about 1/3 the size of Kelleigh units

Switching to water wash not only enhances print outcomes but also modernizes your workflow for sustainability and efficiency.

Anderson & Vreeland: Your Partner in Upgrading Flexo Plate Making Systems

Whether you choose upgrading flexo plate making systems to Vianord solvent systems or transition to Orbital XP water wash technology, Anderson & Vreeland is here to guide you through the process.

We offer:

- Financing options to make equipment upgrades affordable

- Expert technical support for installation and training

Don’t let aging Kelleigh processors hold your operation back. Investing in upgrading flexo plate making systems will future-proof production, improve print quality, and streamline your workflow.

Upgrading flexo plate making systems is no longer a luxury but a necessity for competitive flexographic printing. Explore your options with Anderson & Vreeland to find the perfect fit for your shop’s needs and take your printing to the next level.