Choosing the right exposure unit is a critical step in achieving high-quality flexographic plates and print results. With a range of exposure unit technologies and models available-including several offered by Anderson & Vreeland. It’s important to understand your options and match them to your production requirements. This guide will help you navigate the selection process and highlight the types of exposure units available through Anderson & Vreeland.

What Is an Exposure Unit in Flexography?

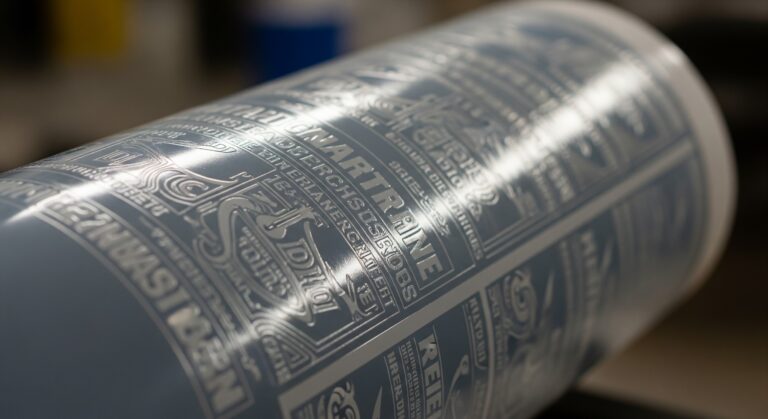

An exposure unit is a device that uses UV light to harden photopolymer plates, creating the relief image that will transfer ink during printing. The quality of this exposure process directly impacts plate durability, print fidelity, and consistency.

Types of Exposure Units

Conventional UV Lamp Exposure Units

Vianord EVO 4 E

- Designed for processing solvent-washable and water-washable, polyester-backed, analogue, and digital plates.

- Maximum plate size: up to 120 x 160 cm (47 x 63 inches), thickness up to 7 mm (0.276 inches).

- High UV output with automatic lamp temperature control and fiber optic lamp failure detection

- Designed for medium web market

Vianord EVO 5 E

- Designed to back-expose and main-finish solvent-washable as well as water-washable, polyester-backed, analogue and digital plates up to a size of 132 x 203 cm (52 x 80 inches) and thickness up to 7 mm (0.276 inches).

- Supports even larger plate formats for high-volume production environments.

- Fully automated plate handling, including imaging, exposure, and transfer, minimizing manual intervention.

- Advanced process control with integrated cameras for live process monitoring and traceability

- This unit features a fully updated temperature control system. The built-in chiller, combined with the advanced air cooling for the lamps and the upgraded water cooling for the exposure table, provides a new standard of temperature control precision.

- Designed for wide web market

Advanced UV LED Exposure Units

Catena E (48 and 80 size)

The ThermoFlexX Catena E series, available in 48 and 80 sizes, offers advanced LED-based exposure technology for flexographic platemaking. The Catena-E 48 supports plates up to 900 x 1200 mm (35 x 48”) with a maximum thickness of 6.35 mm, using traversing and full-coverage UV LED modules for both main and back exposure. Its closed, controlled environment with air extraction ensures consistent, dust-free exposures and high-quality flat-top-dot plates, ideal for precise image reproduction and microstructure detailing.

- The system is designed for fast throughput (up to 6 m²/hr), easy serviceability, and flexible operation—users can choose factory-optimized settings or fine-tune parameters themselves

- Recommended for narrow and wide web markets

Key Factors When Choosing an Exposure Unit

Plate Size and Production Volume

- Select an exposure unit that accommodates your maximum plate size and matches your production throughput. Anderson & Vreeland offers units for a range of plate sizes, from standard to large-format production.

Light Source Technology

- Fluorescent UV Lamps: Reliable and cost-effective, but require regular maintenance and cleaning for consistent output.

- UV LEDs: Offer superior consistency, energy efficiency, and automation potential, minimizing manual intervention and reducing waste.

Automation and Workflow Integration

- Advanced units like the A&V Xpose support workflow automation, reducing manual steps and operator time, and enhancing consistency.

Maintenance Requirements

- Regular cleaning of the exposure unit glass and timely replacement of lamps are essential for optimal performance and plate quality.

Compatibility

Ensure the exposure unit is compatible with the types of photopolymer plates you use (liquid, sheet, digital, or thermal).

Exposure Units from Anderson & Vreeland

Selecting the perfect exposure unit for your flexographic needs involves balancing plate size, production volume, technology, and workflow integration. Anderson & Vreeland provides a comprehensive range of exposure units from conventional UV lamp models to advanced UV LED and digital units to meet the demands of any printing operation. Evaluate your current and future needs, and consult with experts to ensure you invest in an exposure unit that will deliver consistent, high-quality plates and maximize your productivity.

Ready to upgrade your platemaking process? Explore Anderson & Vreeland’s full range of exposure units and take your flexographic production to the next level.