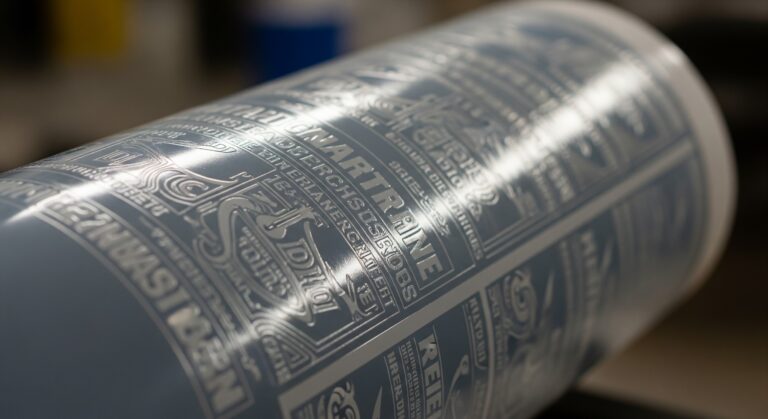

In flexographic printing, the conversation around ROI is often focused on big-ticket expenses: presses, inks, and substrates. But the truth is, the smallest parts, like doctor blades and end seals, can have a dramatic impact on both print quality and profitability.

Too often, these parts are treated like commodities: purchased for the lowest unit cost, swapped out frequently, or, worse, run too long. But thoughtful choices in these consumables can deliver massive returns, reduce downtime, extend anilox roll life, and improve overall pressroom efficiency. That’s Flexo ROI in action.

How the “Bargain Option” Hurts Your Flexo ROI

It’s tempting to see doctor blades as disposable. After all, $5 commodity blades might get a job through a shift or two. But this “low-cost” approach adds up fast. Frequent changes rack up labor costs, steal from press uptime, and risk inconsistent print quality.

Even more concerning, generic blades made from low-grade steel often wear unevenly and can damage expensive anilox rolls—adding thousands of dollars in recovery and replacement costs, not to mention lost production time.

As Andy Gillis, VP and GM of Provident, explains: “Poor blade quality can cost companies $15,000+ a month in roll recovery—and that doesn’t even factor in the opportunity cost of downtime.”

Higher Quality Blades = Higher Flexo ROI

Now, consider a blade that costs three times as much, but lasts up to eight times longer. A properly engineered $15 blade designed with high-chrome steel and specialized coatings can extend runtime to 96 hours. That means fewer blade changes, higher consistency, and fewer interruptions.

For presses where downtime can cost $500–$700 per hour, saving just 30 minutes per blade change adds up to serious money. What looks like a small difference in consumable cost actually translates into thousands of dollars in productivity and profitability across a year.

End Seals: The Quiet Partner in Uptime

Doctor blades and end seals go hand in hand. Like blades, seals are often thought of as generic parts, but the wrong seals can fail under pressure, causing leaks, downtime, and messy, costly cleanup.

On wide-web presses running at high speeds, better-engineered seals are almost like custom-fit shoes: matched to the press to prevent failures and optimized to be replaced in sync with blades. This combination approach reduces set-up time, avoids leaks, and maximizes uptime.

The Cultural Shift: Seeing Consumables as Tools

The key “ah-ha” moment for many converters is realizing that doctor blades and end seals aren’t disposable commodities—they’re tools. And like any other tool, quality matters.

When everyone—president, production manager, and operators—sees the link between consumables and ROI, small changes in purchasing decisions ripple across the business. Investing in long-life blades and engineered seals not only improves print quality but also drives measurable savings.

Why Flexo ROI Matters More Than Ever

In an era where converters compete on speed, consistency, and efficiency, every decision that reduces downtime or improves reliability is a competitive advantage. High-quality doctor blades and end seals safeguard anilox rolls, boost productivity, and protect profitability.

That’s why leading converters, especially those serving household-name brands that demand consistent quality, rely on better consumables. Because in flexographic printing, ROI isn’t just about cutting costs, it’s about investing smart.

Final Takeaway

Doctor blades and end seals may look like small line items on a budget sheet, but they carry big weight in determining printing success. When you prioritize quality over commodity, you unlock better uptime, lower annual costs, and superior print results.

The bottom line? Flexo ROI lives in the details, and even the smallest parts have the power to protect your biggest profits.

Boost quality. Cut costs. Drive results. Partner with Anderson & Vreeland today and get the proven flexo solutions that keep your business competitive and profitable.