Flexographic printing has long been valued for its versatility, speed, and ability to deliver high-quality results across a wide range of substrates. As the demands of packaging, labeling, and product differentiation continue to rise, so too does the need for precision, efficiency, and innovation. Anderson & Vreeland has been at the forefront of this evolution, providing state-of-the-art solutions that set the standard in flexographic technology.

How Digital Imaging Technology Transforms Flexo

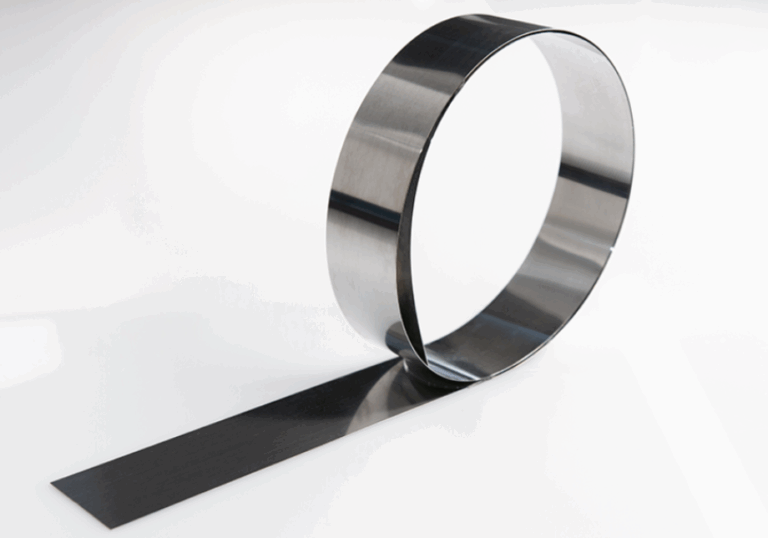

Digital imaging technology is redefining what’s possible in flexographic printing. By integrating advanced digital imagers and workflow solutions, printers can now achieve levels of detail, clarity, and consistency that were once reserved for offset or gravure processes. Digital imaging technology enables the production of high-resolution plates with unparalleled accuracy, ensuring crisp text, smooth gradients, and vibrant images that “pop” on retail shelves.

Key Benefits of Digital Imaging Technology in Flexo

Superior Print Quality: Digital imaging technology allows for the creation of flexographic plates at resolutions up to 5080 dpi, capturing fine details and subtle tonal variations that enhance brand impact.

Workflow Efficiency: Automated digital workflows streamline plate production, reduce manual intervention, and minimize errors, resulting in faster turnaround times and greater productivity.

Consistency and Repeatability: Digital imaging ensures that every plate produced meets exacting standards, reducing waste and rework while maintaining color and image consistency across runs.

Flexibility and Customization: With digital imaging technology, printers can easily accommodate short runs, variable data, and rapid design changes, giving brands the agility to respond to market trends.

Digital Imaging Technology: A Competitive Edge

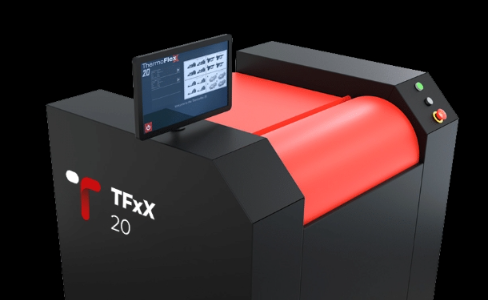

Anderson & Vreeland’s portfolio includes cutting-edge digital imagers and platemaking equipment designed to help printers stay ahead of the curve. By adopting digital imaging technology, flexographic printers can offer their clients higher quality, faster service, and more creative possibilities, all while improving their own bottom line.

“Our advanced flexographic equipment delivers exceptional print quality, efficiency, and sustainability. By constantly pushing the boundaries of what’s possible, we empower our clients to achieve unmatched precision and consistency,” notes Anderson & Vreeland.

Seamless Integration and Expert Support

Transitioning to digital imaging technology is made seamless with Anderson & Vreeland’s expert guidance and support. From evaluating current workflows to integrating new equipment and training teams, A&V ensures that customers harness the full power of digital imaging for their flexographic operations.

The Future of Flexographic Printing

Digital imaging technology is not just a trend; it’s the new standard for flexographic printing. As brand owners demand more vibrant packaging, faster turnarounds, and sustainable processes, digital imaging technology positions flexo printers to deliver on every front. Anderson & Vreeland remains committed to driving this revolution, helping customers achieve excellence today and into the future.

For more on how digital imaging technology can transform your flexographic printing, consult the experts at Anderson & Vreeland for tailored solutions and unrivaled expertise.