At Anderson & Vreeland, we pride ourselves on delivering comprehensive flexographic printing support to help our customers achieve optimal print quality and operational efficiency.

Flexographic Printing Support in Action

When a long-standing client, traditionally a high-end envelope printer, ventured into label printing with a new Nilpeter press, they encountered unexpected banding issues that threatened their business and customer commitments. This case study highlights how our technical expertise and collaborative approach resolved their challenges and reinforced our value as a trusted flexographic printing support partner.

The Challenge: Banding Issues on a New Nilpeter Press

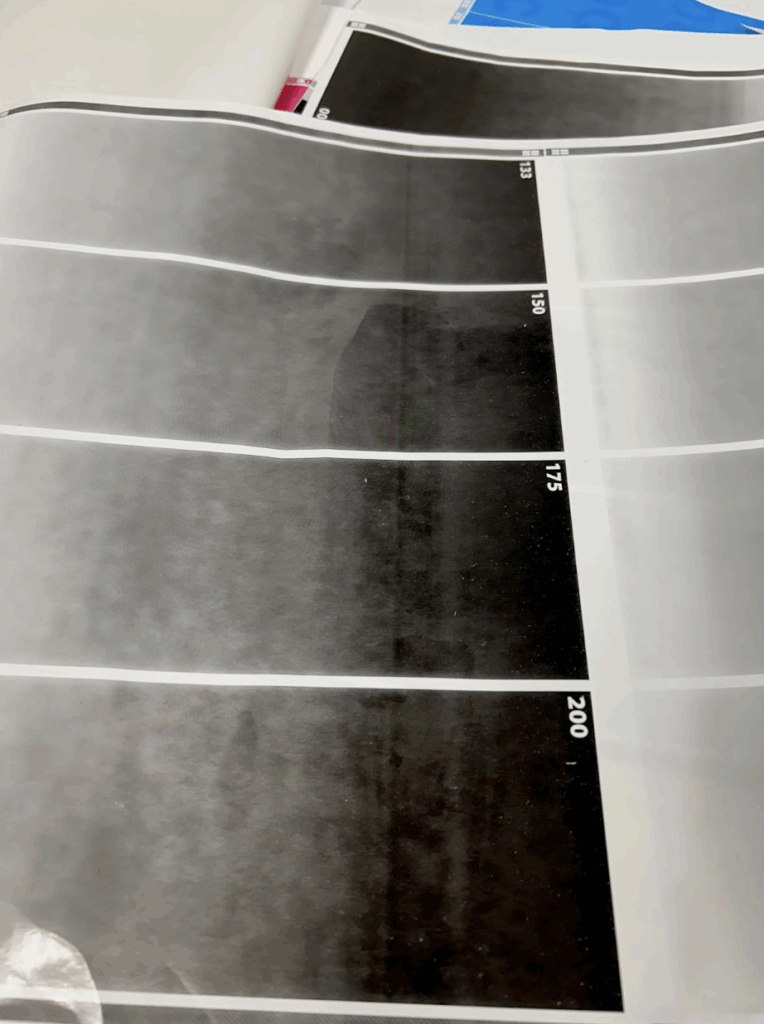

Our customer, Mac Papers, installed a Nilpeter press to expand into label printing. Despite their experience with envelope printing, they faced persistent banding (bouncing marks) in all processes and screened artwork immediately after installation. The banding made it impossible to run screened jobs, putting their new venture and customer promises at risk.

For years, Mac Papers had relied on XSYS ACT solvent plates from Anderson & Vreeland and recently converted all their plates to our solutions. However, after two months of trying to resolve the issue themselves, and with Nilpeter suggesting the plates were at fault and recommending a competitor’s product, they reached out to us for advanced flexographic printing support.

The Investigation: Collaborative Flexographic Printing Support

Once contacted, our team at Anderson & Vreeland responded quickly. Bryan Thrasher offered to visit immediately, but due to scheduling and the Flexographic Technical Association (FTA) event, the visit was postponed. Meanwhile, Mac Papers sought advice from multiple industry experts at FTA, yet the banding persisted.

We initiated remote flexographic printing support via Teams, reviewing tape and other variables with our internal experts, Kelly Vaughan and Wendy Chan. We also shipped a new 3M 1215H tape for trial, aiming to isolate the cause of the banding.

Onsite Flexographic Printing Support: Diagnosing the Real Issue

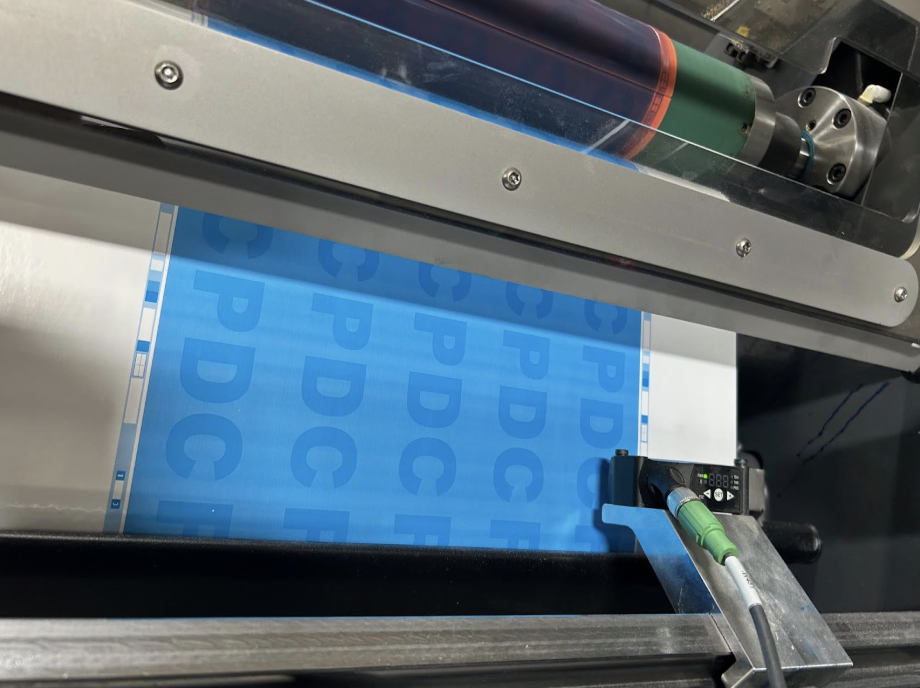

Bryan Thrasher became the first technical expert onsite after FTA. Together, we reviewed all variables: plate making, mounting tapes, and press settings. We requested Mac Papers to create a test plate with specific parameters and mount it on the new tape, as well as to remount known jobs.

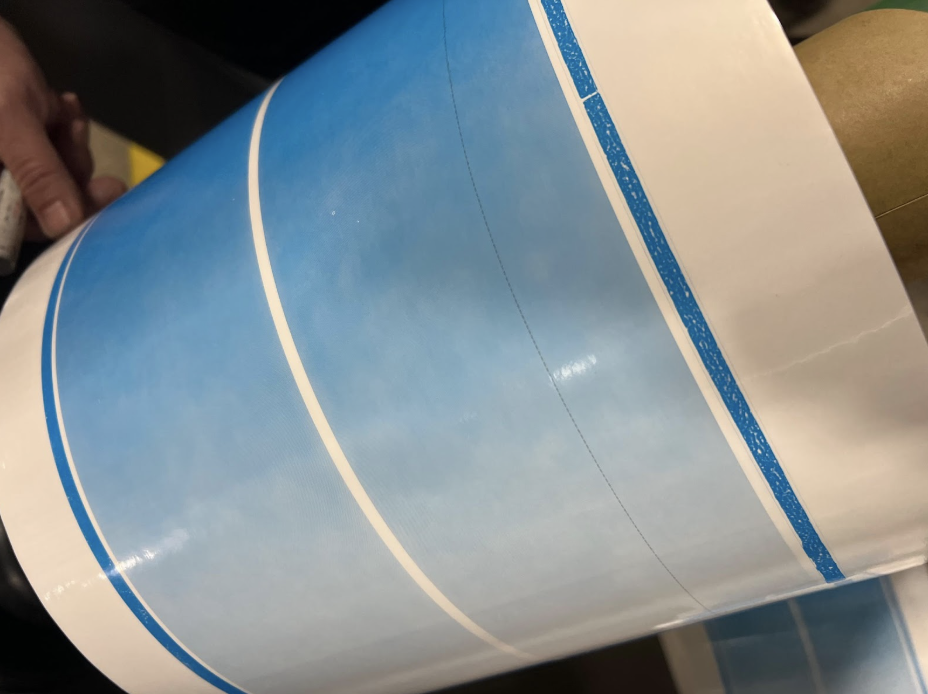

Test prints showed significant improvement with the new plate and tape combination, but older plates still exhibited banding. Swapping press units confirmed the issue was not isolated to one unit or plate. At this point, we consulted with Tim Brannon, who suggested the problem could be related to press tension settings, a critical factor when working with new substrates like BOPP, which Mac Papers had not used before.

The Solution: Expert Flexographic Printing Support Resolves Banding

Tim Brannon visited Mac Papers the following week. In less than an hour, he worked with their team to adjust the Nilpeter press tension controls. The result was immediate and dramatic: the banding issue vanished entirely. The root cause was not the plates or tape, but improper tension settings, a common challenge when transitioning to new substrates and press technologies.

The Outcome: Renewed Confidence and Lasting Partnership

Thanks to Anderson & Vreeland’s swift and thorough flexographic printing support, Mac Papers was able to:

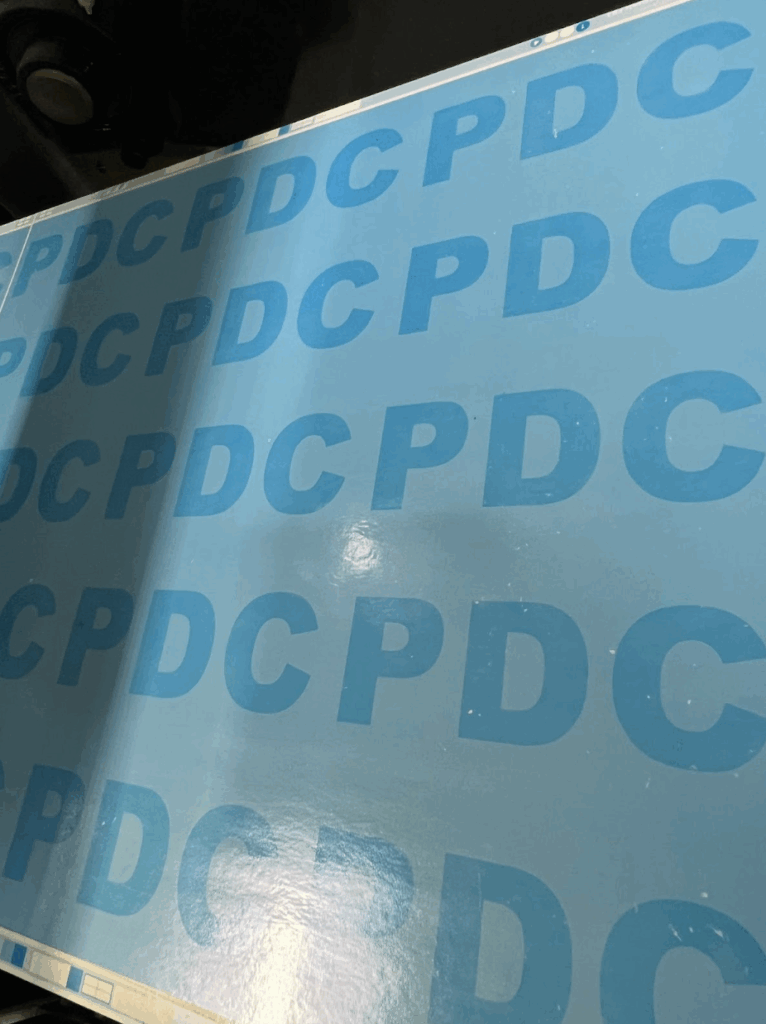

• Eliminate banding and resume running screened jobs as promised to their customers

• Regain confidence in their Nilpeter press investment and our XSYS ACT ECO plates

• Commit to fingerprinting their presses exclusively with our plates

• Consider Anderson & Vreeland for all future consumable needs

Our collaborative troubleshooting, onsite support, and technical expertise not only resolved a critical production issue but also reinforced our reputation as a reliable partner for flexographic printing support.

The Value of Expert Flexographic Printing Support

This case study demonstrates the importance of expert flexographic printing support when facing technical challenges, especially during transitions to new equipment or substrates. Anderson & Vreeland’s proactive approach, deep industry knowledge, and commitment to customer success ensured a positive outcome for Mac Papers and a strengthened partnership for the future.

If your operation faces similar challenges or is considering new flexographic printing technologies, trust Anderson & Vreeland for the support and solutions you need to succeed.

Contact us today to learn how our flexographic printing support can help you achieve flawless print results and operational excellence.