When you think about what drives your business, the flexographic presses on your shop floor likely come to mind first. They’re the workhorses, the revenue generators, and the centerpiece of your operation. But what about the equipment working quietly in the background? Flexographic support equipment may not be as flashy as your presses, but these essential tools are every bit as vital to your company’s productivity, safety, and bottom line.

Why Flexographic Support Equipment Matters

It’s easy to take flexographic support equipment for granted. Yet, without the right tools in place, even the best press can’t deliver its full potential. From demounters and plate mounters to cleaning systems and storage solutions, support equipment streamlines workflows, protects your investment in plates and sleeves, and reduces downtime.

Preventing Pressroom Injuries with Flexographic Support Equipment

Let’s focus on a critical yet often overlooked piece of flexographic support equipment: the demounter. At first glance, a demounter might seem like a luxury item—something only the largest shops need. But in reality, it’s a powerful tool for improving safety and efficiency.

Manually removing plates and tapes from sleeves and rollers can be physically demanding, especially on mid- and wide-web presses. Press operators sometimes resort to awkward, risky maneuvers just to get plates off, putting themselves at risk for back, shoulder, and joint injuries.

The cost of even a single workplace injury can be significant, including lost productivity, increased insurance premiums, and the potential for long-term health issues. Investing in the right flexographic support equipment, like a demounter, can help prevent these injuries, safeguard your workforce, and keep your shop running smoothly.

Boosting Efficiency and Plate Longevity

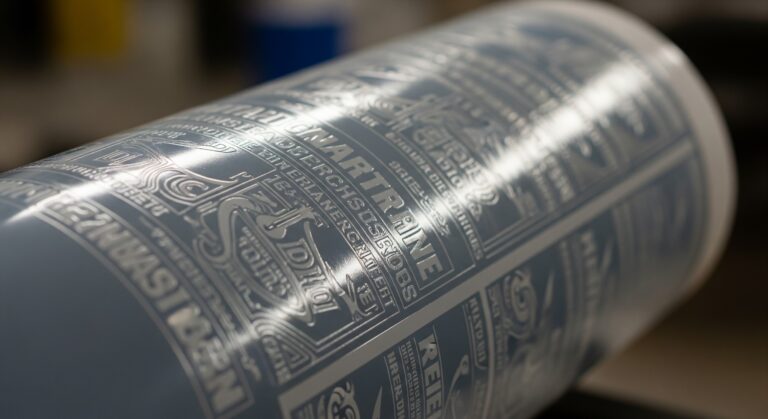

The benefits of flexographic support equipment go beyond safety. Demounters, for example, are much faster than manual removal, cutting non-productive time and allowing your team to focus on value-added tasks. Plates removed with a demounter are less likely to tear or kink, making them easier to clean and store for future use, saving money and reducing waste.

Spotlight on Bieffebi Mounters

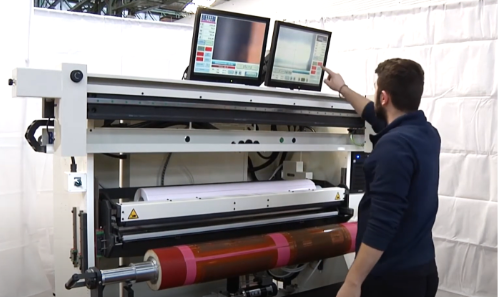

Among the leading brands in flexographic support equipment, Bieffebi mounters stand out for their precision, innovation, and reliability. Bieffebi offers a comprehensive portfolio of plate mounters designed to meet the diverse needs of modern flexo shops, ranging from straightforward tabletop models to advanced, fully automated systems.

Equipped with patented technologies like the Virtual Data Processing (VDP) system and advanced optical registration solutions, Bieffebi mounters deliver exceptional accuracy and repeatability for plate mounting jobs, including gearless applications. These features help minimize mounting errors, speed up setups, and ensure plates are mounted perfectly every time, enhancing both efficiency and print quality.

The intelligent automation and quality control functions, such as automatic plotters for marking mounting lines and innovative devices that prevent air bubbles and delamination, can reduce mounting times while safeguarding plates and sleeves for longer-lasting performance. Incorporating Bieffebi mounters into your workflow means fewer costly mistakes, reduced downtime, and a smooth path to consistently high-quality print results.

Anderson & Vreeland recently highlighted the benefits of our new mounting solutions in Label and Narrow Web. Our innovative mounting and demounting technologies simplify the plate mounting process, ensuring greater precision and efficiency in print production. These new solutions integrate seamlessly into existing workflows, improving accuracy while reducing setup times and waste, which ultimately enhances overall operational productivity.

Expert Guidance on Flexographic Support Equipment

Choosing the right flexographic support equipment can be overwhelming. That’s where Anderson & Vreeland’s Equipment Team comes in. Our team of technical and operations experts evaluates every aspect of your workflow, identifying opportunities to save time, reduce costs, and maximize efficiency.

We look at everything: cleaning solutions, cylinder and sleeve mandrels, plate washing systems, storage solutions, and more. Our recommendations are based on decades of hands-on experience and up-to-date industry knowledge, ensuring you get the best equipment for your specific needs.

Planning for the Future: Support Equipment for New Presses

When you invest in a new press, it often comes with new requirements—different sleeves, updated plate mounters, or specialized storage. Anderson & Vreeland’s Equipment Team stays ahead of the curve, often knowing about new press models before they hit the market. We work with you to identify the flexographic support equipment you’ll need, helping you get the most from your new investment from day one.

By consulting with our team before your new press arrives, you can shorten the ramp-up time and start seeing a return on your investment sooner.

Stay Competitive with the Right Flexographic Support Equipment

In today’s competitive market, every minute and every dollar counts. With thinner staffing and tighter budgets, many shops no longer have the in-house expertise to keep up with the latest trends in flexographic support equipment. That’s why partnering with a knowledgeable team like Anderson & Vreeland’s can make all the difference.

Ready to discover how the right flexographic support equipment can improve safety, efficiency, and profitability in your pressroom? Contact your Anderson & Vreeland account manager today and put our aptitude to work for you.