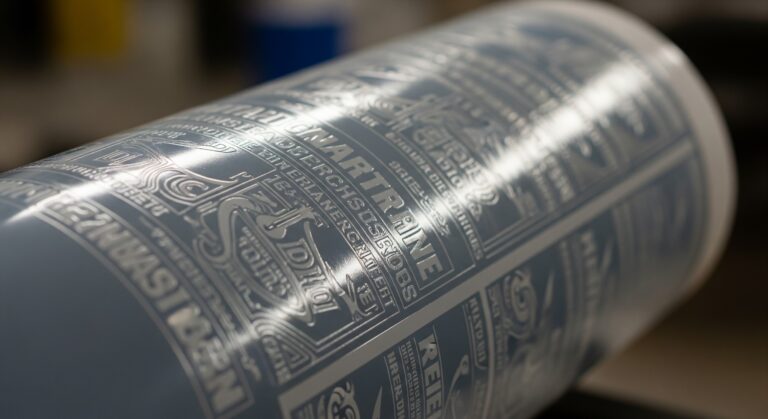

Flexographic printing demands precision, speed, and order—qualities that are all too often lost to inefficient storage systems. That’s where Flexopodz step in. Anderson & Vreeland is proud to offer Flexopodz, a modular and innovative storage solution tailored for the specific needs of flexographic printers, helping operations unlock more floor space, streamline workflow, and improve plate and sleeve care.

Why Flexopodz are the Industry's Top Storage Solution

A major challenge in any print facility is maximizing usable space. With Flexopodz, users report up to 80% capacity gain after converting to mobile storage systems that eliminate aisles and optimize each shelf. Flexopodz achieves these results through modular design, vertical storage for sleeves to prevent warping, and customizable configurations that fit your facility’s unique needs.

- Sleeve storage holds up to 50% more per shelf by using vertical orientation, preserving sleeve quality, and saving floor space.

- Plate storage uses flat, image-down stacking in custom boxes, widely recognized as the gold standard for preserving graphics and preventing damage.

- Ink storage employs robust, heavy-duty shelving that handles thousands of pounds, ensuring safety and durability.

Boost Efficiency and Employee Satisfaction

Time wasted searching for plates, sleeves, or inks is time that could be spent on production. Flexopodz can reduce average retrieval time from over 30 minutes to just three minutes per job—a potential savings of over $20,000 in labor annually for facilities running six jobs a day. This drastic improvement not only cuts costs but also helps maintain employee retention by reducing daily frustration and repetitive labor.

Protect Your Plates and Sleeves the Right Way

Proper storage is critical for extending the lifespan of valuable flexographic plates. Flexopodz’s climate-aware designs and guided best practices protect sensitive polymers from drying, cracking, and UV damage—a concern echoed in industry best practices and technical guides. Custom boxes, environmental controls, and the system’s automated inventory tracking further safeguard the integrity of your materials.

Smarter Inventory Management: Built-In Tracking and Automation

Flexopodz integrates seamlessly with your existing inventory management systems to support automation, job-ticket integration, lifecycle alerts, and guided material retrieval. This ensures every asset is accounted for, easily located, and tracked for usage, mileage, and reprinting needs—a game-changing approach for busy pressrooms.

Safety and Compliance, Built In

Each Flexopodz unit comes with safety-first engineering, including push-to-lock handles, anti-tip floor mounts, seismic-safe rails, and robust construction. Professional installation and warranty packages deliver peace of mind for every investment.

Modular, Scalable, and Future Proof

Whether your operation is growing or you just want flexibility to reconfigure storage down the line, Flexopodz adapts easily. Its modular design lets facilities add units, reconfigure layouts, and keep pace with changes in production volume or product lines.

Anderson & Vreeland: The Flexographic Experts

For over 60 years, Anderson & Vreeland has delivered innovative solutions tailored to the evolving needs of flexographic printers. The addition of Flexopodz to our portfolio demonstrates our commitment to helping every customer optimize space, improve workflow, and safeguard their equipment and materials for years to come.

Ready to put Flexopodz to work for your printing operation? Contact Anderson & Vreeland today for a tailored solution and reclaim your workspace with the industry’s most advanced flexographic storage solution.