The label printing industry is undergoing a significant transformation, fueled by advances in digital color, workflow solutions, and the power of the internet. These innovations are creating a new convergence in label printing, offering label-converting shops unparalleled opportunities to enhance efficiency, boost profitability, and drive growth. At the heart of this revolution is hybrid software workflow automation and integration, a suite of tools designed to streamline production processes and harness the potential of these converging technologies.

Transforming Label Printing with Hybrid Software

Hybrid Software offers an integrated approach to managing digital workflows in label printing. It eliminates duplicate data entry, reduces human error, and automates production processes. These capabilities translate into lower costs, improved performance, and a more efficient production environment for label converters.

“Hybrid Software provides the ‘missing link’ between MIS systems, web-to-print portals, and prepress workflow,” explains an Anderson & Vreeland representative. “Hybrid’s product line has expanded to include automated production workflows, customizable job ticketing, customer-facing e-commerce portals, resource-based scheduling, and version control for critical production files.”

Key Features of Software Solutions for Labels and Packaging Printing

Hybrid Software’s suite of products addresses four critical areas of label printing workflow:

- Customer-Facing Web Portals (Frontdesk): Seamless portals allow customers to interact directly with the production process, improving communication and order accuracy.

- Job Ticketing & Automation (Facelift, Pipeline, Fileforce, Taskforce): These tools enable efficient job management by automating repetitive tasks, ensuring precision, and optimizing resources.

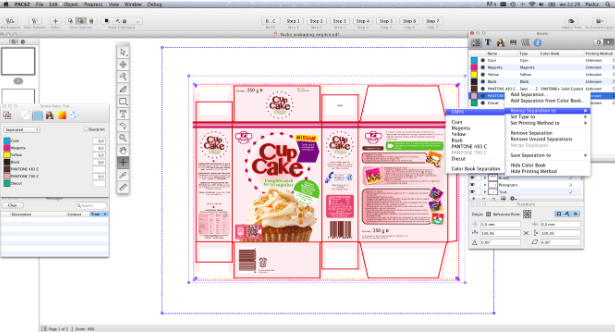

- Soft Proofing and Editing (Proofscope, PACKZ): Featuring PACKZ, the industry’s only native PDF editor, this suite offers comprehensive prepress, editing, and quality assurance functions, such as trapping, separation handling, barcode creation, and dynamic info panel generation.

- Production Workflow (Cloudflow): A cloud-based workflow engine that integrates seamlessly with existing systems, Cloudflow ensures that production processes are streamlined and error-free.

Spotlight on PACKZ: The Native PDF Editor for Label Printing

One standout product in the Hybrid Software lineup is PACKZ. As the only native PDF editor designed specifically for label printing, PACKZ offers a complete set of tools for prepress, editing, and quality assurance. Its robust feature set includes:

- Trapping for flawless color management

- Advanced separation handling

- Barcode creation and recognition

- Dynamic creation of information panels

- Object-based screening for high-precision printing

With PACKZ, label converters can achieve greater accuracy and efficiency, ensuring high-quality output for even the most demanding projects.

Driving Innovation and Profitability in Label Printing

Adopting Hybrid Software for Label Printing Workflow positions label-converting shops to meet the challenges of modern production head-on. By integrating customer-facing tools, automating processes, and ensuring top-notch quality control, Hybrid Software empowers businesses to stay ahead of the competition and capitalize on new market opportunities.

The Future of Digital Workflows in Label Printing

As the label printing industry continues to evolve, the integration of cutting-edge software like Hybrid Software will play a pivotal role in shaping its future. By embracing these tools, label converters can unlock new levels of productivity, profitability, and growth.

Whether you’re looking to enhance your existing workflow or explore new possibilities, Hybrid Software offers the solutions you need to succeed in a rapidly changing landscape.

Ready to transform your label printing workflow? Discover how hybrid software solutions for labels and packaging printing can revolutionize your operations today. Contact the Anderson & Vreeland team to learn more.