Ask any box printer today what matters most, and you’ll hear the same answer again and again: faster turnarounds, consistent quality, and cost efficiency. In a world where customers expect one- or two-day delivery timelines, the need for speed and reliability on press is greater than ever.

One tool that continues to rise in importance is the liquid photopolymer plate. With durable performance, faster production times, and greener processing methods, liquid photopolymer plates are helping printers and trade shops meet evolving demands while improving both print quality and efficiency.

The Fast-Track Advantage of Liquid Photopolymer Plates

Not long ago, a three- to five-day turnaround time was industry standard. Today, many customers expect jobs in one or two. Liquid photopolymer plates can be created in about one-third of the time required for sheet plates, making them a smart fit for converters and trade shops looking to get jobs to press faster.

They’re also lighter in weight, especially with island plate technology, which saves on shipping costs and makes handling easier for press operators. For converters producing copy and graphics on corrugated containers, these factors deliver a clear competitive advantage.

Flexibility with Recycled Substrates

Anyone printing on today’s corrugated boards knows that substrates have changed. Thanks to higher levels of post-consumer waste, surfaces are often less consistent and more challenging for ink transfer.

Here, liquid photopolymer plates offer an advantage. Their lower durometer allows them to adapt to uneven recycled surfaces, improving ink lay-down and print consistency. That means better coverage, fewer reprints, and the ability to hit tight customer deadlines without compromising quality.

The Science Behind the Magic

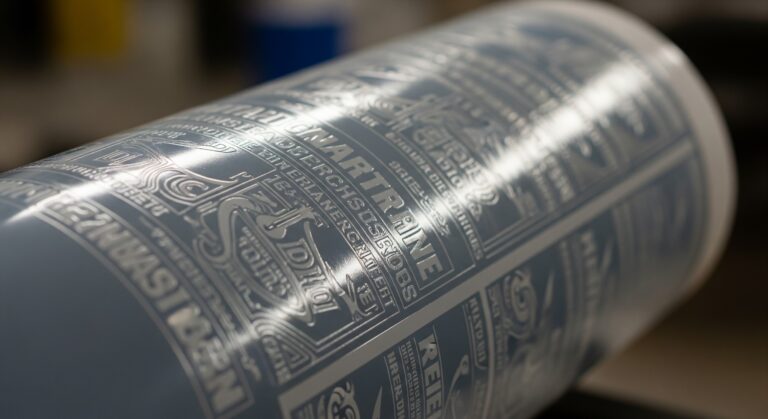

There’s something almost magical about the process: viscous polymer resin is poured into a mold, sealed, exposed to UV light, and transformed into a durable plate that can run hundreds of thousands of impressions. It’s materials science at work, yet still a wonder to see.

Durability comes down to durometer, or hardness.

For example:

• Corrugated substrates may demand softer 25–34 Shore A durometer plates to handle surface variation.

• Multi-wall bags or films often require mid-range hardness, like 55 Shore A.

• Molded products may need harder 80–90 Shore A plates for strength and longevity.

For even greater precision, capping resins, combining a harder surface layer with a softer, more compressible base, can balance ink transfer with long-term durability, delivering superior print results across demanding applications.

Care, Maintenance, and Storage

While durable, liquid photopolymer plates demand thoughtful care. Because they cure with UV light, too much additional exposure (from sunlight or warehouse lighting) can cause brittleness. Proper storage away from strong UV sources is essential to preserve plate quality.

Cleaning and processing, though, are refreshingly sustainable. Liquid photopolymer plates use water-based chemistry and can be cleaned with soap and water. Their environmentally conscious waste stream is even compatible with most municipal sewage systems—a major win in regions with strict chemical disposal regulations.

Pressroom Integration: Raising the Bar on Quality

Adding liquid photopolymer plates into your production workflow does more than speed up turnarounds. By combining better plates with clean presses, conditioned anilox rolls, and quality consumables like doctor blades and end seals, printers can elevate consistency across every job.

This is increasingly important as more box makers expand from basic one- or two-color imprints to retail-ready packaging with multicolor graphics. In this environment, small improvements in substrates, plates, and press setup all add up to significant gains in uptime, quality, and competitiveness.

Why Liquid Photopolymer Plates Matter Today

• Faster plate production = quicker turnarounds and faster speed to market.

• Lower durometer flexibility = better print results on recycled substrates.

• Environmentally friendly = water-wash processing supports greener operations.

• Adaptability = durometer range and capping solutions fit a wide array of applications.

• Cost efficiency = lighter plates reduce shipping costs and operator strain.

Ultimately, liquid photopolymer plates aren’t just an alternative to sheet plates—they’re part of a smarter, more flexible approach to modern flexographic printing. They allow converters and trade shops to take on more jobs, deliver faster, and maintain the consistent quality today’s customers expect.

Final Takeaway

In flexo, every detail matters, from substrates to plates to consumables. By leveraging the speed, flexibility, and sustainability of liquid photopolymer plates, converters can transform fast turnaround times and superior ink transfer from challenges into competitive strengths.

Because when the market demands faster, cleaner, greener printing, the right plates help make it possible.

Your success is our priority. From expert guidance to cutting-edge technology, Anderson & Vreeland delivers the support you need to take your print operations further—let’s grow together.