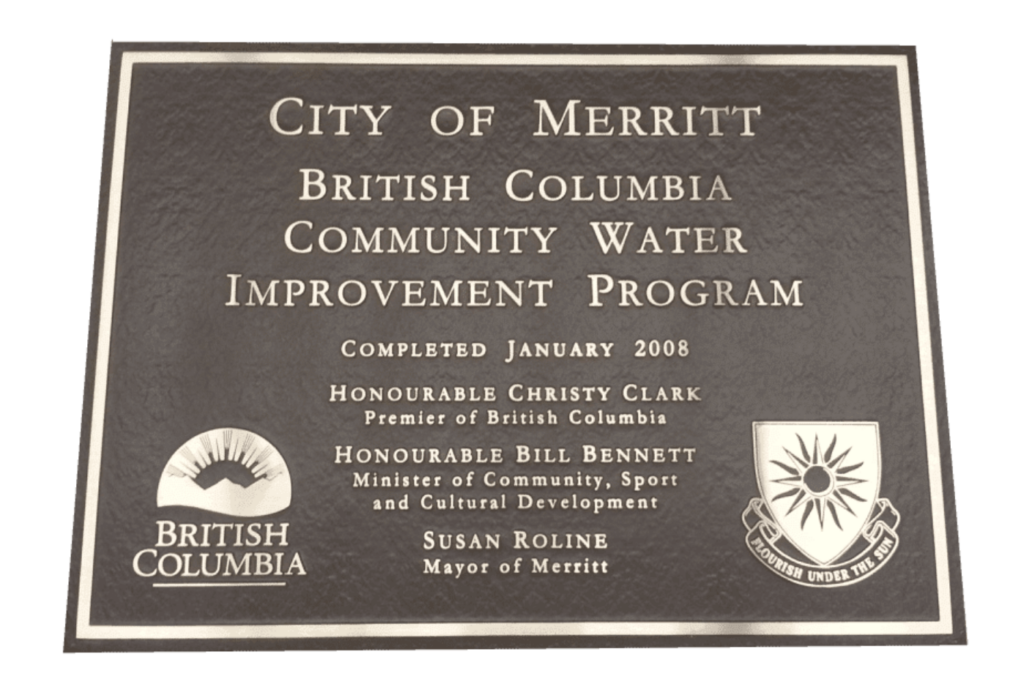

Ornamental Bronze, a distinguished British Columbia company, specializes in creating plaques, signage, memorials, and castings from bronze, brass, and aluminum alloys. Their work embodies the blend of artistic expression and functional design, turning ideas into customized metal creations that commemorate businesses, governments, and individuals.

At the heart of their production process lies the use of liquid photopolymer plates, which have revolutionized the way Ornamental Bronze achieves consistent quality and improved productivity.

Transitioning to Liquid Photopolymer Plates

Before adopting liquid photopolymer technology, Ornamental Bronze relied on sheet photopolymer plates (25” x 30” x .112) that fell short of delivering consistent quality and ideal relief depth. Recognizing these limitations, A&V Canada introduced a 30” x 40” plate processing system designed to leverage the advantages of liquid photopolymer plates.

The AVantage liquid photopolymer material provided deeper relief depths—up to .150—enabling Ornamental Bronze to produce deep etch plaques with superior precision. “A&V’s equipment and materials provide a more consistent product with deeper relief, and we have much better quality control over the finished plate,” said Noel Edmonds, Typesetter at Ornamental Bronze.

Benefits of Liquid Photopolymer Plates

The shift to liquid photopolymer plates brought several transformative benefits:

- Enhanced Quality:

The deeper relief achieved with liquid photopolymer improved the detail and precision of the plaques and castings, ensuring high-quality results that exceeded client expectations. - Increased Productivity:

The 30” x 40” plate processing system allowed for the production of more plates in a single run. This efficiency, combined with the reusability of liquid photopolymer material, significantly reduced waste and lowered material costs. - Cost Savings:

Liquid photopolymer is more affordable than traditional sheet plates, and the ability to reclaim unused material further minimizes expenses.

A Fourfold Increase in Production

The investment in liquid photopolymer plates and A&V’s advanced equipment has led to remarkable improvements for Ornamental Bronze. According to Noel Edmonds, “The product coming off A&V equipment is remarkable compared to what was previously used. When A&V first installed the new equipment, I realized it would probably increase our production by four times, and we are very close to achieving that.”

Unparalleled Support from A&V Canada

Switching to new equipment and materials often comes with challenges, but A&V Canada ensured a seamless transition. Angela Maud, Office Manager at Ornamental Bronze, praised the comprehensive support they received: “A&V made every effort to solve any problem that has arisen,” offering assistance through in-person visits, phone calls, and online support from their Canadian and U.S. teams.

Transform Your Production with Liquid Photopolymer Plates

Ornamental Bronze’s success story highlights the transformative impact of liquid photopolymer plates on quality, productivity, and cost efficiency. For companies seeking to elevate their production processes, investing in advanced plate technology like liquid photopolymer can deliver exceptional results while streamlining operations.

Explore how liquid photopolymer plates can revolutionize your business by providing superior results and maximizing efficiency.