In flexographic printing, staying ahead of the competition means embracing innovations that improve efficiency, quality, and sustainability. One such breakthrough is extended gamut flexo printing, a technique revolutionizing how printers achieve vibrant, consistent, and cost-effective results.

This blog explores what extended gamut flexo printing is, how it works, and why it’s becoming the go-to solution for modern printing operations.

What Is Extended Gamut Flexo Printing?

Extended gamut flexo printing refers to the use of a fixed set of inks—typically cyan, magenta, yellow, and black (CMYK), plus additional colors like orange, green, and violet (OGV)—to reproduce a wider range of colors. By expanding the standard CMYK gamut, this method reduces the need for custom spot colors, achieving greater color accuracy and consistency across a variety of designs.

How Does Extended Gamut Flexo Printing Work?

Extended gamut printing utilizes advanced color separation software and high-precision flexographic equipment to layer inks in a way that mimics spot colors. This approach eliminates the need for frequent ink changes during a print run, significantly reducing downtime and waste.

Key components that make this process possible include:

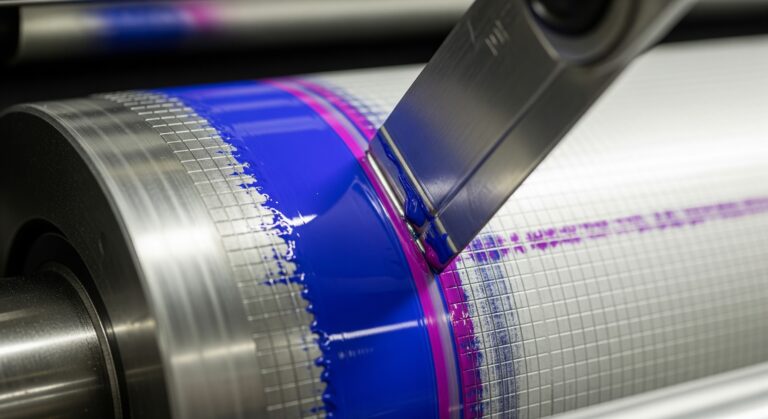

- High-quality anilox rolls for precise ink transfer

- Advanced flexo plates for detailed image reproduction

- Color management software to ensure accuracy

- Standardized inks for predictable results

The Benefits of Extended Gamut Flexo Printing

- Cost Savings

By eliminating the need for custom spot colors, printers save money on ink inventory and reduce setup times. This efficiency translates to cost savings for both printers and their clients. - Enhanced Color Range

With the addition of OGV inks, extended gamut flexo printing delivers colors that are more vibrant and true to the original design, creating stunning visuals that stand out. - Faster Turnaround Times

Because the ink set remains fixed, printers can switch between jobs without lengthy cleanup or ink changes, allowing for quicker production schedules. - Sustainability

The reduced waste and lower energy consumption associated with this method contribute to a more eco-friendly printing process, aligning with the industry’s push for greener solutions.

Applications of Extended Gamut Flexo Printing

Extended gamut flexo printing is particularly beneficial for:

- Packaging: Vibrant, eye-catching designs for consumer products

- Labels: Consistent branding across multiple SKUs

- Flexible Packaging: High-quality printing on non-rigid materials

- Retail Displays: Bold visuals that demand attention

This technique is ideal for industries that prioritize color consistency and high-quality finishes, such as food and beverage, cosmetics, and pharmaceuticals.

Challenges to Consider

While extended gamut flexo printing offers many advantages, it requires investment in specialized equipment, software, and training. Additionally, achieving consistent results depends on strict adherence to color management protocols. Partnering with experienced professionals and reliable suppliers is key to overcoming these challenges.

Why Choose Extended Gamut Flexo Printing?

For companies seeking to elevate their branding and streamline production, extended gamut flexo printing is a game-changer. It provides a perfect balance of quality, efficiency, and sustainability, making it an excellent choice for modern printing needs.

Extended gamut flexo printing represents the next frontier in flexographic printing. By embracing this innovative method, printers can meet the growing demand for exceptional color quality and fast turnaround times while maintaining a competitive edge in an increasingly dynamic market.

Are you ready to explore the possibilities of extended gamut printing? Upgrade your operations today and experience the difference!