Label printing has always been a critical component of packaging and branding, helping businesses convey their identity and provide essential product information. Today, technological advancements in flexographic label printing are pushing the boundaries of what’s possible, offering greater efficiency, precision, and creativity. Let’s explore how these new technologies are revolutionizing the label printing industry.

Digital Advancements in Label Printing

Digital technologies have transformed traditional label printing, providing new levels of customization and efficiency. Key innovations include:

- Digital Flexo Printing: Combining the strengths of flexographic and digital printing, this technology allows for high-resolution labels with variable data capabilities, making it ideal for personalized or short-run projects.

- Automated Plate Mounting: Automation in plate mounting reduces errors and setup times, enabling faster turnaround without compromising print quality.

- Smart Color Management Systems: Advanced software solutions now ensure color accuracy across different print runs, maintaining brand consistency and minimizing waste.

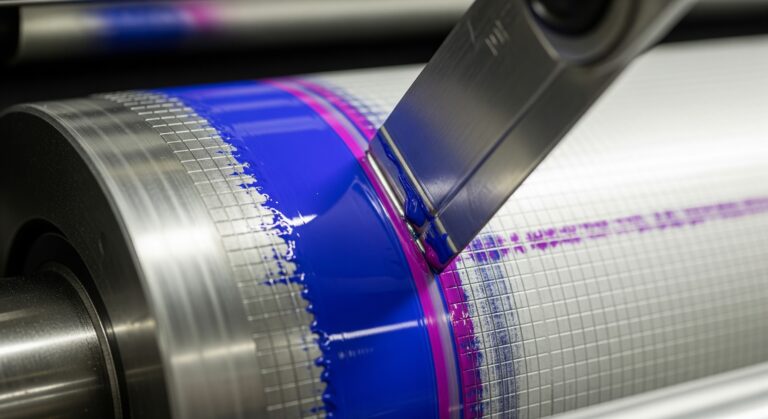

Extended Gamut Printing in Flexographic Label Printing

One of the most significant advancements in flexographic label printing is extended gamut printing (EGP). By using a fixed set of inks (typically CMYK plus orange, green, and violet), EGP achieves:

- Vibrant Colors: Producing a wider range of hues that rival traditional spot colors.

- Cost Efficiency: Reducing the need to mix custom inks, which simplifies inventory and speeds up production.

- Sustainability: Minimizing ink waste and energy consumption.

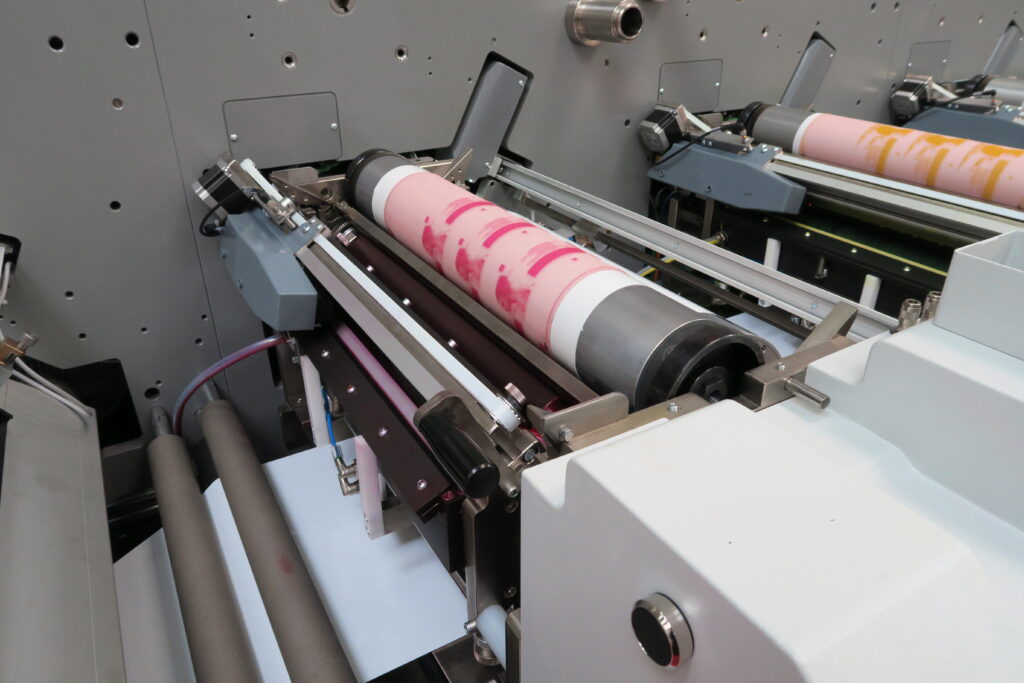

Innovations in Plate Technology for Label Printing

Flexo plates are the backbone of any flexographic label printing operation. Recent improvements include:

- High-Density Photopolymer Plates: These plates offer superior ink transfer, enabling sharper images and text.

- Flat-Top Dot Technology: Ensuring consistent ink laydown, flat-top dots enhance print quality, particularly for fine details and gradients.

- Eco-Friendly Plate Materials: New photopolymer materials are designed with sustainability in mind, reducing the environmental impact of plate production.

Automation and Workflow Optimization

Modern label printing operations leverage automation to streamline processes and boost productivity:

- Smart Press Controls: Automated adjustments for speed, tension, and ink levels reduce downtime and ensure consistent quality.

- Integrated Workflow Systems: From design to final production, integrated software platforms improve collaboration and reduce manual errors.

- Inspection and Quality Control: Advanced inspection systems detect defects in real-time, ensuring only flawless labels reach the market.

The Role of Sustainability in Label Printing

Environmental concerns are driving innovations in sustainable label printing practices. Flexographic printing has embraced this trend by:

- Using Water-Based Inks: These inks are less harmful to the environment and meet regulatory standards for food and beverage packaging.

- Reducing Waste: Enhanced precision in printing and materials usage minimizes waste throughout the production process.

- Energy-Efficient Equipment: New plate processor designs use less energy while maintaining high-speed output.

The Future of Label Printing

As technology continues to evolve, the label printing industry will see further innovations, including the integration of AI for predictive maintenance, real-time analytics, and even more personalized printing solutions. These advancements will empower brands to achieve stunning, high-quality labels faster and more sustainably than ever before.

Final Thoughts

The advancements in flexographic label printing technologies are reshaping the way labels are designed and produced. By adopting these innovations, businesses can enhance efficiency, reduce costs, and create visually stunning labels that capture consumer attention. Whether you’re looking to improve print quality or embrace sustainability, the future of label printing is brighter than ever.

Ready to elevate your label printing with cutting-edge technology? Contact Anderson & Vreeland today to explore innovative solutions that will enhance your efficiency, quality, and sustainability in flexographic printing.