One of the advantages of being in business for over fifty years is that we’ve witnessed numerous changes in the world of flexo, and pad printing has certainly evolved over time.

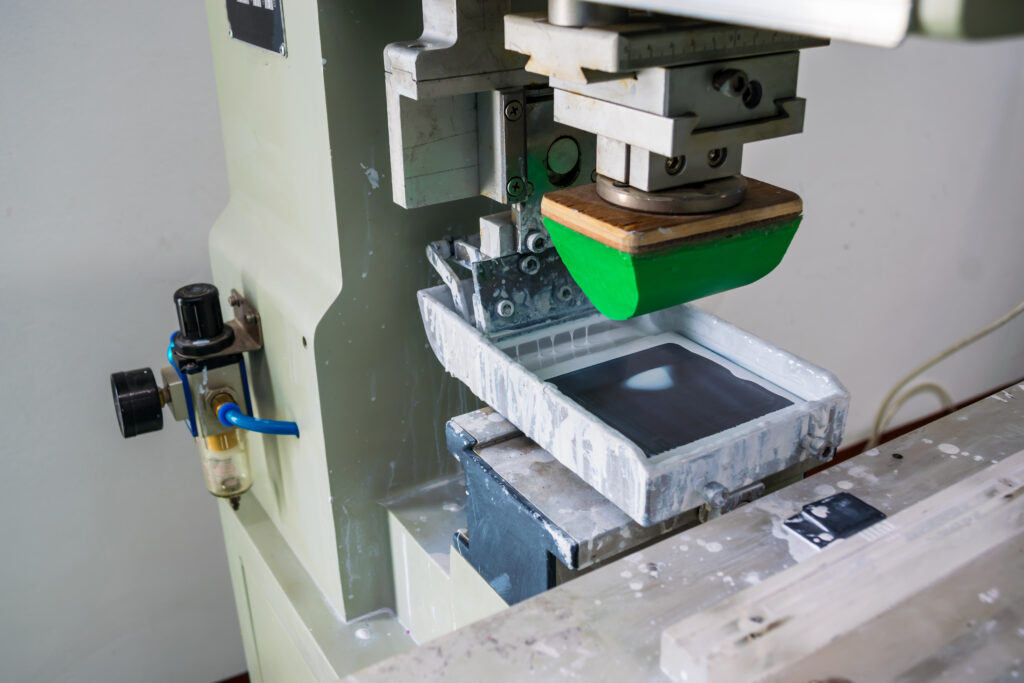

For those unfamiliar, pad printing is a versatile process that allows you to transfer 2D images onto 3D objects, much like a rubber stamp. The process involves a silicone pad, which picks up ink from a laser-etched plate and then presses it onto the surface of the product. This results in a crisp, high-quality printed image. The technology behind pad printing has improved significantly over the years, with advancements in flexo plate materials playing a key role in these improvements.

How to Improve Your Pad Printing

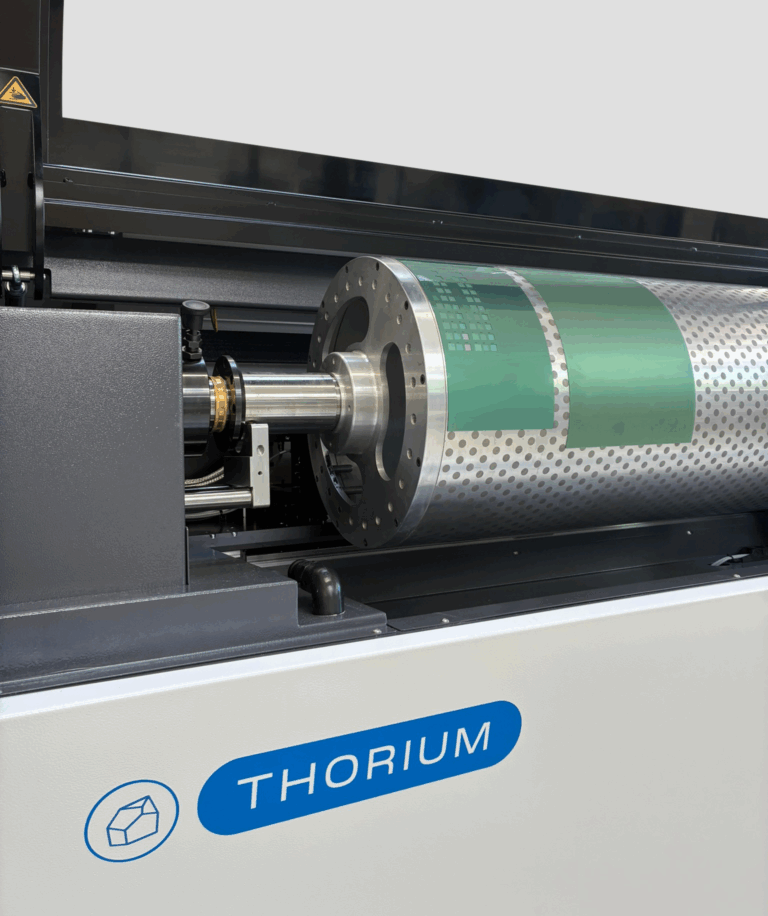

In particular, pad printing plates have become more efficient, durable, and capable of delivering superior results. Leading manufacturers, such as XSYS, offer a range of specialized plates designed specifically for pad printing. Below are some of their top offerings:

nyloprint® DLE 30 S – Ideal for Precision Pad Printing

The nyloprint® DLE 30 S is a direct engravable pad printing plate that offers the highest print quality. This plate is designed for fast, efficient, and consistent processing, making it a favorite for industrial and promotional product printing. With a resolution of up to 305 lpi (120 L/cm) and the ability to handle up to 30,000 impressions, the DLE 30 S is reliable and reusable for repeat orders, offering exceptional solid density and screen ruling.

nyloprint® S – A Cost-Effective Pad Printing Solution

The nyloprint® S is an alcohol-washable gravure plate that provides excellent print quality for pad printing applications. It’s ideal for both promotional and industrial products, offering screen ruling up to 305 lpi (120 L/cm). This plate is fast to process, offers a wide exposure latitude, and is suitable for jobs with up to 30,000 impressions. It’s a productive and cost-effective option for many businesses looking to maximize efficiency.

nyloprint® ST – The Ultimate Pad Printing Plate for Long Runs

For those looking for the highest print quality in pad printing, the nyloprint® ST offers a resolution of up to 10.160 dpi and a screen ruling up to 380 lpi (150 L/cm). This alcohol-washable gravure plate is designed for durability, making it perfect for long print runs of over 30,000 impressions. The optimized relief formulation enhances its efficiency and durability, ensuring that the plates can handle large-scale production with ease.

nyloprint® WS and WS Digital – Brilliant Pad Printing for Diverse Applications

nyloprint® WS and WS Digital are water-washable steel-based plates designed for a wide range of pad printing applications. These plates offer exceptional print quality with high resolution, smooth vignettes, and brilliant halftone gradations, making them ideal for printing on a variety of products, including laminated tubes, cups, cans, and security printing. The fine halftone dots (< 20 micron) ensure brilliant tonal range and print contrast, perfect for high-end pad printing applications.

nyloprint® WSA and WSA Digital – Superior Durability for High-Volume Pad Printing

The nyloprint® WSA and WSA Digital plates are water-washable gravure plates that offer the best print quality for pad printing. With resolutions up to 10.160 dpi and screen ruling up to 380 lpi (150 L/cm), these plates provide excellent solid density and durability for long print runs of over 20,000 impressions. Optimized for high-quality, high-volume jobs, they are an excellent choice for demanding pad printing projects.

Pad Printing Plates that Meet Market Demands

XSYS’s pad printing plates have played a crucial role in meeting the ever-growing demands of various industries. With a range of materials designed to deliver top-notch performance, selecting the right plate can sometimes be challenging. If this summary doesn’t address your specific needs or you have further questions about pad printing, feel free to reach out to our Technologies Team at Anderson & Vreeland for personalized guidance.