The commercial flexographic printing industry is experiencing rapid transformation, driven by technological innovation, sustainability demands, and evolving customer expectations. For operations aiming to scale successfully, understanding and leveraging these trends is essential. Here’s how your business can achieve sustainable growth and operational excellence in commercial flexographic printing.

The Growth Trajectory of Commercial Flexographic Printing

Commercial flexographic printing continues to expand globally, with the market projected to reach $10.25 billion in 2029, fueled by the rising demand for flexible packaging and labels. This growth is supported by the technology’s versatility, cost-effectiveness, and ability to deliver high-quality results across a wide range of substrates.

Key Strategies for Scaling Commercial Flexographic Printing Operations

1. Embrace Automation and Digital Integration

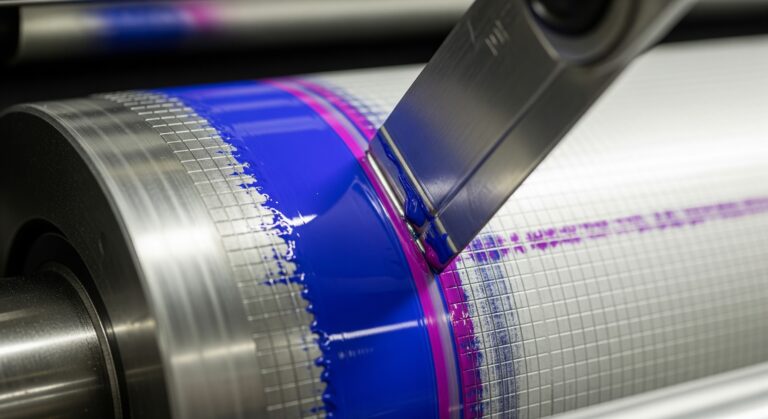

Automation is revolutionizing commercial flexographic printing by streamlining workflows, reducing errors, and boosting productivity. From automated plate imaging and color matching to job setup and quality control, digital integration enables faster turnaround times and greater consistency. Investing in automated solutions not only increases output but also frees up operators to focus on higher-value tasks.

2. Prioritize Sustainability

Sustainability is no longer optional in commercial flexographic printing. Customers and regulators alike demand eco-friendly practices, pushing printers to adopt sustainable inks, substrates, and processes.

Upgrading to energy-efficient equipment, implementing waste reduction initiatives, and sourcing recyclable materials all contribute to a greener operation and a stronger market position.

3. Expand Customization and Short-Run Capabilities

The trend toward personalization is reshaping commercial flexographic printing. Modern presses and workflow solutions make it possible to efficiently handle short runs and customized jobs, catering to brands that value agility and unique packaging. Hybrid presses that combine flexo and digital printing offer the flexibility to switch between long and short runs without sacrificing quality or efficiency.

4. Invest in Advanced Color Management

Consistent, high-quality color is critical in commercial flexographic printing. Implementing advanced color management systems ensures accurate color reproduction, reduces waste, and increases customer satisfaction. Real-time monitoring and automated correction technologies further enhance print quality and operational reliability.

5. Foster Strategic Partnerships

Collaboration with suppliers, technology providers, and industry experts is vital for scaling commercial flexographic printing operations. Strategic partnerships provide access to the latest innovations, technical support, and market insights, enabling your business to stay ahead in a competitive landscape.

Innovations Shaping the Future of Commercial Flexographic Printing

- Integrated Combination Machines: These systems combine flexo with other processes, such as die-cutting or digital printing, in a single workflow, increasing versatility and efficiency.

- Modular Press Designs: Customizable modules allow for rapid adaptation to changing production needs, supporting both large-scale and niche applications.

Partner with Anderson & Vreeland for Scalable Success

Scaling your commercial flexographic printing operation requires more than just the right equipment; it demands a partner with deep industry expertise and a commitment to your success. Anderson & Vreeland delivers innovative solutions, technical support, and ongoing education to help you navigate the evolving landscape of commercial flexographic printing and achieve your growth goals.

Ready to scale your success? Connect with Anderson & Vreeland to explore the latest advancements and tailored solutions for your commercial flexographic printing operation.