Flexography is the backbone of modern packaging, delivering vibrant, high-quality prints on a wide range of substrates. At Anderson & Vreeland, we know you demand precision, speed, and reliability. Understanding the flexography process and leveraging the right products is key to staying ahead in a competitive market.

What Is the Flexography Process?

The flexography process is a high-speed, roll-to-roll printing technique that uses flexible photopolymer plates to transfer ink onto various substrates, from paper and film to foil and nonwovens. Its versatility, efficiency, and ability to handle long runs make it the preferred choice for packaging, labels, and more.

Key Stages of the Flexography Process

1. Prepress: The Foundation of Quality

- Artwork Preparation: The journey begins with precise digital artwork. Anderson & Vreeland partners with market leaders such as GMG and Hybrid to provide advanced preflight and file management solutions, ensuring your designs are optimized for flexo printing and color management is dialed in from the start.

- Plate Making: High-quality plates are essential. Anderson & Vreeland offers a complete range of plate processing equipment, including thermal, water-wash, liquid, and solvent systems. Leading brands like XSYS, EVO systems by Vianord, and Anderson & Vreeland ensure exceptional plate quality, consistency, and speed.

2. Plate Mounting and Press Setup

- Mounting Plates: Accurate plate mounting is crucial for registration and print clarity. Anderson & Vreeland supplies industry-leading mounting tapes like 3M and Tesa, paired with rotec® sleeves and adapters, designed for precision and efficiency during plate mounting.

- Pressroom Supplies: From custom end seals and doctor blades for every application to digital proofing supplies and cleaners, Anderson & Vreeland can help you bundle consumables to create a cost-takeout strategy, and also provides RFID tags for inventory management.

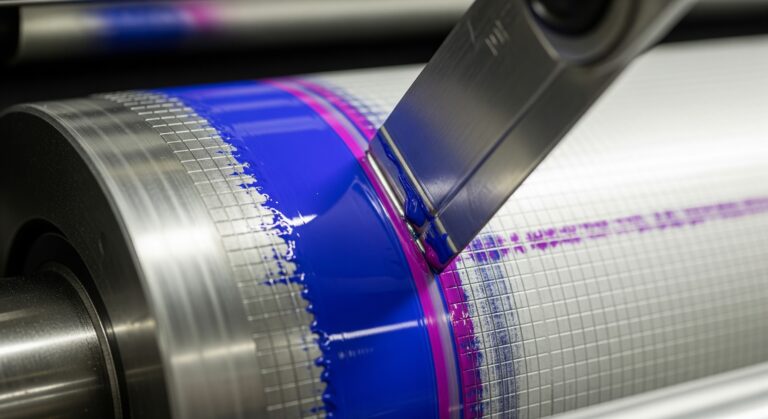

3. The Printing Stage

- Ink Application: The flexography process uses anilox rollers to deliver a controlled, even layer of ink to the plate. Anderson & Vreeland’s pressroom solutions ensure optimal ink transfer and color consistency across every run.

- Substrate Feeding: Roll-fed substrates pass through the press, guided by tension controls for smooth, accurate movement, minimizing waste and maximizing quality.

4. Image Transfer and Drying

- Printing: The inked plate transfers the image onto the substrate with precision, thanks to the high-quality plates and press components sourced from Anderson & Vreeland’s trusted partners.

- Drying/Curing: Depending on ink type, drying may involve hot air, infrared, or UV/LED systems. Anderson & Vreeland can advise on the best drying technology for your specific application.

5. Post-Press and Quality Control

- Finishing: Once printed, materials may be slit, die-cut, or laminated. Anderson & Vreeland’s workflow solutions ensure quality is maintained throughout.

- Inspection: Quality control is streamlined with advanced proofing software and color management tools like GMG, ICScolor, Techkon, and X-rite, guaranteeing your final product meets the highest standards.

Anderson & Vreeland: Your Partner in the Flexography Process

With over 60 years of expertise, Anderson & Vreeland stands out as a comprehensive resource for the flexography process. Our consultative approach, extensive product portfolio, and technical support ensure you have everything needed for success, from prepress to pressroom and beyond.

Benefits of High-Quality Splicing Tape

Investing in high-quality splicing tape offers several benefits:

- Reduced Downtime: Reliable splices minimize web breaks and machine stops, keeping production lines running smoothly.

- Improved Print Quality: Consistent splices prevent misprints and ensure uniform tension throughout the roll, resulting in higher print quality.

- Lower Costs: By minimizing waste and maximizing efficiency, high-quality splicing tape can significantly reduce overall production costs.

- Enhanced Productivity: Seamless production leads to increased output and faster turnaround times, boosting overall productivity.

Featured Brands & Products

| Stage | Anderson & Vreeland Solutions |

|---|---|

| Prepress | Digital workflow, color management, proofing software, digital imagers |

Plate Room | Thermal, solvent, water-wash, liquid photopolymer plates, platemaking equipment, and rotec® sleeves |

Pressroom | Mounting and splicing tapes, cleaners, doctor blades, end seals, safety and industrial supplies, RFID inventory |

Service & Support | Nationwide technical support, installation of sold equipment, and training |

Why Choose Anderson & Vreeland for Your Flexography Process?

- One-stop shop: Complete solutions from file to finished print

- Industry-leading brands: Access to top equipment and consumables

- Expert support: Decades of experience and hands-on technical guidance

- Innovation: Stay ahead with the latest in flexo technology and training resources

Ready to Optimize Your Flexography Process?

Contact Anderson & Vreeland today to discover how custom solutions, products, and expertise can elevate your flexographic printing operation. Whether you’re upgrading equipment, streamlining workflow, or seeking technical support, Anderson & Vreeland is your trusted partner for every stage of the flexography process.