In the quest for brighter, whiter paper, optical brightening agents (OBAs) have emerged as heroes of the printing industry. These additives, which fluoresce under UV light, provide a cost-effective solution to enhance the whiteness of paper. However, as with any technological advancement, integrating OBAs into printing processes comes with its own set of challenges, particularly in color consistency and standardization.

Understanding Optical Brightening Agents

Optical brightening agents are additives infused into paper during its production process. These agents absorb UV radiation and re-emit it as visible light, typically in the blue-violet range, which enhances the perceived brightness and whiteness of the paper. This optical illusion makes the paper appear brighter to the human eye, even though the paper remains unchanged.

The Rise of OBAs and Color Matching Challenges

The widespread adoption of OBAs has led to a surge in demand for brighter paper. However, this surge has been accompanied by challenges in color matching, particularly due to variations in the UV content of light sources used for viewing printed materials. Historically, standards for viewing conditions and measuring devices did not adequately address the UV content in light sources, leading to inconsistencies in color perception across different environments.

ISO Standard 3664: A Beacon of Clarity

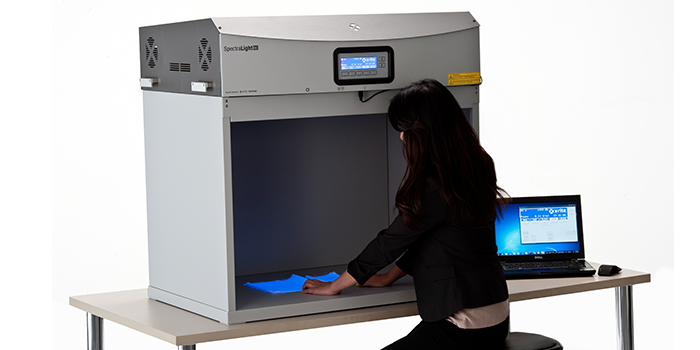

In 2009, the International Organization for Standardization (ISO) addressed these challenges by publishing ISO Standard 3664, which outlines specific conditions for viewing and comparing proofs to prints. Crucially, this standard includes a more defined specification for the amount of UV content in light sources, ensuring greater consistency in color perception across different viewing environments.

Navigating the New Standards

For those in the printing industry, particularly those who already utilize light booths for color evaluation, the implementation of ISO Standard 3664 may necessitate some adjustments. Here’s what you need to know:

Bulb Compliance: If you’ve replaced your light booth bulbs from a graphic arts source within the last two years, chances are they comply with the new standards. However, if your bulbs are older, it’s advisable to replace them to ensure compliance.

Impact on OBA Printing: If you print on substrates containing OBAs, you may start noticing differences between proofs and press samples. This is due to the heightened sensitivity of OBAs to UV content in light sources.

Adapting Light Booths: Some manufacturers offer filters that can remove UV content from the light source to maintain visual consistency in light booths. While this may achieve a visual match, it does not fully comply with the latest standards.

Meeting the Latest Standards: To ensure compliance with the latest standards and achieve accurate color matching, profiles may need to be recreated using the new M1 measuring light source standard, which includes a defined amount of UV content.

The Impact of Optical Brightening Agents

Optical brightening agents have revolutionized the printing industry, offering a cost-effective solution for achieving brighter paper. However, their integration into printing processes necessitated reevaluating color standards and viewing conditions. With ISO Standard 3664 providing a clear framework for color evaluation, printers can navigate the challenges posed by OBAs while ensuring consistency and quality in their printed materials. By staying informed and adapting to evolving standards, printers can continue to deliver vibrant, visually stunning results to their clients.

For expert support and additional information, reach out to Anderson & Vreeland today. Our team is ready to assist you with all your printing needs and provide tailored solutions.