Plate mounting is a pivotal step in the flexographic printing process, impacting registration accuracy and plate longevity. Proper handling and mounting techniques are crucial to prevent defects, registration issues, and downtime on the press. Here are essential guidelines and tips for achieving excellence in plate mounting.

The plate mounting department is a critical area for ensuring good registration on press as well as the long run-life of the plate. If plates are handled poorly during mounting, the result could be defects in print, registration problems, ink-transfer issues, and/or press downtime due to plate lift or sleeve/cylinder failure. Please see our tips below for plate handling and mounting guidelines.

Plate Mounting FAQs and Best Practices

Is checking bearings an important part of mounting when mounting directly to the cylinder for a label press?

Yes. A simple spin of the bearing can determine if it’s good or bad and can prevent downtime on the press. Bearings that don’t spin freely should be greased or replaced if damaged.

Is it important to clean all grease and ink from cylinders?

Yes. Grease or other contaminants can cause high spots or plate lift. It is always a good idea to clean with Isopropyl Alcohol or Acetate.

What is the main purpose of applying tape or hot-melt glue in the plate gap?

To prevent solvents or inks from working their way between the plate and sticky back or sticky back and cylinder. This helps prevent plate lift.

Can a dull plate cutting blade contribute to plate lift?

Yes. Instead of cutting, a dull blade will actually burst through, leaving a burred edge on the polyester side of the plate. This prevents good contact with the sticky back.

Would you clean a plate with a standard bristle brush?

If using a brush to wipe or clean plates, the bristles need to be soft so the dots are not damaged. A horse hair brush or a Pamarco Care Pad is preferred. Also, no woven fabrics – these will catch and shear off small dots.

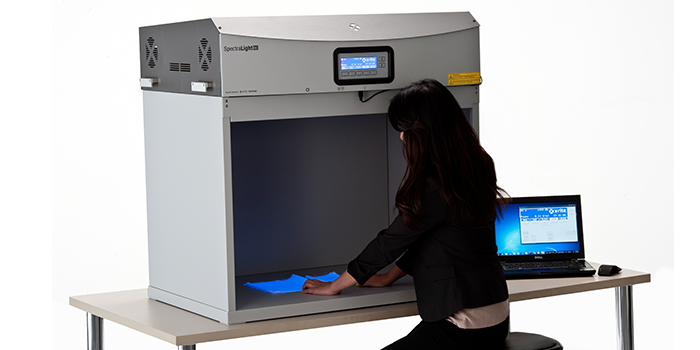

Is it safe to clean photopolymer plates with basically any cleaner we find on the shelf?

No. Many cleaners can have chemicals harmful to plates. Many cleaners contain solvents that may change the surface characteristics of the plate and, therefore, the print. Isopropyl Alcohol is generally recommended. However, always check with the plate manufacturer for the best/recommended plate cleaning solution.

Are Mag 44 markers and 3M’s primer 94 two ways to increase the surface tension of a plate for increased adhesion plate to the tape?

Yes, these promote adhesion, but will not prevent solvents from penetrating the bond between tape and plate or tape and cylinder.

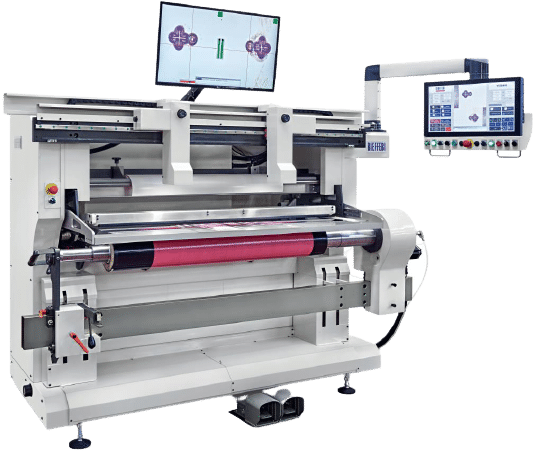

What’s the best tool for laying down a plate?

In most cases, a brayer, not your hand. However, there are many new devices with safety in mind where a brayer is no longer needed, providing less wear and tear on the operator’s hands and wrists.

Is an interleaf between plates helpful in storage?

Yes. The foam interleafed between the plates from the manufacturer works best. Never store a plate print-surface to print-surface.

Can cornstarch or talc powder be used to deaden the adhesive properties of the tape in areas exposed?

Yes. Many operators will remove that tape; however, keeping tape along the length of the cylinder is a way to keep cylinders clean. The use of powder reduces the tackiness for easier handling.

Can hypodermic needles be used to get rid of air bubbles?

As long as you are piercing through the floor of the plate.

What is the best location to line your cameras up on the plate? Tail or middle?

Middle. The easiest and most efficient way to get a plate-mounted square is by starting in the middle of the plate.

Can rounded corner cuts prevent plate tear during de-mounting?

Demounting a staggered-cut plate with 90-degree corners without tearing the plate is extremely difficult. It is recommended to round the internal corners to help reduce plate tear during demounting.

Can cracked sleeves be used with care to avoid blow-out or cutting an employee?

The best solution is to remove the damaged sleeve from production and repaired or replaced by the OEM.

What is an easy way to work with sleeves with notches?

Order the sleeves notched for both sides. A double notch can prevent mounting in the wrong rewind position.

Should you clean the backs of plates with Isopropyl Alcohol or Acetate before use?

Yes. If left dirty, this can create high spots or plate lift. It is always a good idea to clean with Isopropyl Alcohol.

Do I need a maintenance program for mounting devices?

Taking scheduled time to keep equipment in top running shape helps prevent downtime during critical times.

High-Quality Flexographic Prints with Plate Mounting

Mastering plate mounting is essential for achieving high-quality flexographic prints and ensuring the longevity of your plates. Proper handling and mounting techniques are critical to avoid common issues such as defects, registration problems, and press downtime. By adhering to the best practices outlined above, you can enhance print accuracy, prevent plate lift, and maintain optimal press performance.

For further assistance or more information on plate mounting and other printing solutions, don’t hesitate to reach out to Anderson & Vreeland. Our experts are here to help you optimize your printing processes and achieve the best results.