Flexographic printing demands precision, efficiency, and consistent quality—requirements that hinge on the choice of narrow web doctor blades. Anderson & Vreeland, as a trusted provider partnering with Provident, delivers a suite of advanced doctor blades tailored for the narrow web environment and optimized for today’s high-performance presses.

Why Narrow Web Doctor Blades Matter

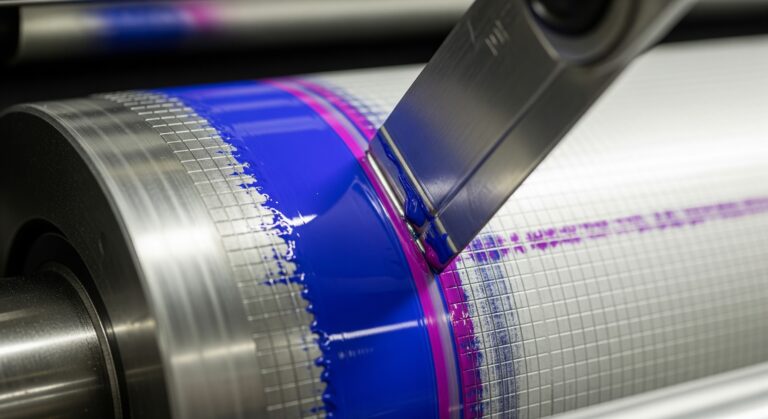

Narrow web doctor blades are essential for metering ink from the anilox roller, ensuring accurate color laydown and crisp print results. More than 50% of the flexographic industry still uses basic radius tip blades, though as blade tips wear, inconsistencies like dot gain and print defects arise. Upgrading to higher-quality, application-specific doctor blades helps achieve predictable results, reduce waste, and streamline press operations.

Evolving Standards: Precision Engineering by Provident

Anderson & Vreeland features Provident’s narrow web doctor blades, available in a variety of materials, profiles, and performance coatings. Steel blades offer durability and fine edge precision, while coated blades and nano-treated options deliver enhanced longevity and stability—even under demanding press speeds or challenging inks. Specialized profiles like lamella, wing lamella, and bevel tips can be selected for fine detail work, long runs, or high-pressure jobs, bringing consistent results across print environments.

Benefits of Selecting the Right Doctor Blade

• Longer blade life: High-grade steel and advanced coatings mean less tip wear and fewer blade changes—the key to smoother runs and reduced downtime.

• Better print consistency: Custom-tailored blades meter ink more precisely, eliminating the need for corrective on-press adjustments.

• Reduced operational costs: Informed blade selection minimizes waste, protects assets like anilox rollers, and improves ROI for packaging and label printers.

• Flexibility: Provident doctor blades adapt to specific press setups, business goals, and substrates, ensuring optimal results whether printing for regional brands or national campaigns.

Anderson & Vreeland’s Narrow Web Doctor Blade Solutions

Anderson & Vreeland supports flexographic printers with:

• Provident steel, coated, plastic, and nano-treated doctor blades for narrow web applications.

• Expert consultation to match blade profiles and tips to each unique print job and chamber design.

• Technical support and resources for optimizing ink control and troubleshooting press challenges.

Partner for Print Excellence

Leveraging Anderson & Vreeland’s industry expertise and Provident’s advanced blades, printers gain a partner in process efficiency, innovation, and sustainable print performance. Each press operation is unique; by selecting tailored narrow web doctor blades, operators can achieve sharper graphics, consistent output, and competitive differentiation on every run.

Need help finding the right narrow web doctor blade? Anderson & Vreeland is ready to guide you through selection, trial, and integration—delivering the solution that enhances productivity and print quality for your flexographic needs.